The tutorial for the LCD screen will use the basic 1602 type from Hitachi!! This has been cloned to death... Everyone has a copy of this chip set down to mimicking its every function..

I use “Displaytech” and “Fordata” mainly because of the cost... I'm certainly not advertising them.. Use whatever you have... But they have served me well over the past few years...

To use these devices you have to set them up before you can use them.... The chip set can use a variety of sizes, the main ones being 16 character by 2 line, 20 character by 2 line, 16 character by 4 line and 20 character by 4 line.

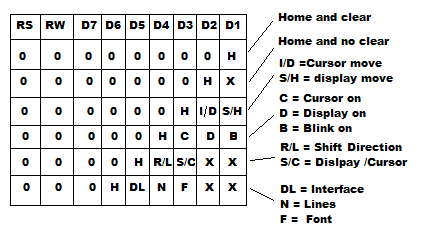

The basic commands for the display set up are shown here..

This is the start of the digital communication age... devices talking to other devices we can control various devices by addressing, commands and data... As we move on through the next few tutorials we will see more and more “control” over the way we read and write to sensors and displays..

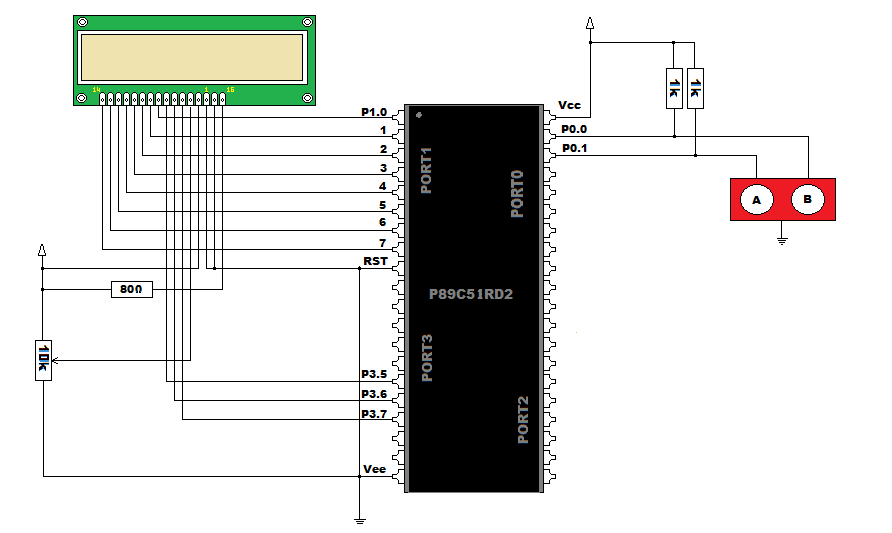

I have connected an LCD to our circuit.. The data lines D0~D7 are connected to P1 of our micro and the three control lines RS, RW and E are connected to P3 of our micro..

The display has 16 pins D0~D7, RS, RW, E , Vo, Vcc and Vee, we also have the Cathode and Anode for the back light.. The screen I use uses an LED back light that needs 20mA at 4.2 volts..

This needs a current limiting resistor of 0.8v /20mA ( Ohms law ) = 40 ohm resistor... This will give optimal lighting, however! I try to give the LED its best life so I decrease the current to 10mA to prolong its life... As the daylight reflection isn't too bad and the display is still readable in the dark and the light, so I use an 80 ohm resistor to limit the back light current.. ( nearest value = 82R )

The display also needs a contrast!! The contrast varies from manufacturer to manufacturer... The small 5mm digit sized displays run with a contrast of 5 volts... Bigger displays need more contrast voltage... This can be up to 17 volts. This voltage is almost always referenced from the Vcc rail down... So the display I use has a maximum of -5 volts.... I use a small negative voltage generator... Namely the ICL7660, a small 8 pin IC that can produce the negative of the voltage that is supplied.. In our case +5 volts will produce -5 volts to generate the negative voltage the LCD contrast needs.

For your convenience just use the single rail type... then the contrast will fall between 5 volts and ground...

I have written the ASM and C code to write to the LCD screen and display messages and user input information..

Code 13

From the code above you will see that all the commands are made by manipulating the data and control lines ( buses ). By writing several low level “device drivers” then several High level routines, we have proper control over the device connected to port 1

LcdPrint can be called to print an entire NULL terminated string to the display.. Almost automating the process.

The C code version starts to show the big differences when programming.... We can use strings as simply as typing them out.. If you examine the differences in the code, you start to understand the ease without the mundane programming.... I do not want to discourage ASM coding as its the nuts and bolts that all compilers are built on....

I program comfortably in both environments so I can get to grips with both... I have written oodles of line of code in ASM and in C.. You can include ASM into C code to make the timing aspect of ASM possible in C...

Here's my representation of the code in C.... Representation because the code WILL start to differ greatly..

Code 14

I am hopefully going to upload the serial communication tutorial next. Simple micro ~ PC stuff....

Enjoy!

I use “Displaytech” and “Fordata” mainly because of the cost... I'm certainly not advertising them.. Use whatever you have... But they have served me well over the past few years...

To use these devices you have to set them up before you can use them.... The chip set can use a variety of sizes, the main ones being 16 character by 2 line, 20 character by 2 line, 16 character by 4 line and 20 character by 4 line.

The basic commands for the display set up are shown here..

This is the start of the digital communication age... devices talking to other devices we can control various devices by addressing, commands and data... As we move on through the next few tutorials we will see more and more “control” over the way we read and write to sensors and displays..

I have connected an LCD to our circuit.. The data lines D0~D7 are connected to P1 of our micro and the three control lines RS, RW and E are connected to P3 of our micro..

The display has 16 pins D0~D7, RS, RW, E , Vo, Vcc and Vee, we also have the Cathode and Anode for the back light.. The screen I use uses an LED back light that needs 20mA at 4.2 volts..

This needs a current limiting resistor of 0.8v /20mA ( Ohms law ) = 40 ohm resistor... This will give optimal lighting, however! I try to give the LED its best life so I decrease the current to 10mA to prolong its life... As the daylight reflection isn't too bad and the display is still readable in the dark and the light, so I use an 80 ohm resistor to limit the back light current.. ( nearest value = 82R )

The display also needs a contrast!! The contrast varies from manufacturer to manufacturer... The small 5mm digit sized displays run with a contrast of 5 volts... Bigger displays need more contrast voltage... This can be up to 17 volts. This voltage is almost always referenced from the Vcc rail down... So the display I use has a maximum of -5 volts.... I use a small negative voltage generator... Namely the ICL7660, a small 8 pin IC that can produce the negative of the voltage that is supplied.. In our case +5 volts will produce -5 volts to generate the negative voltage the LCD contrast needs.

For your convenience just use the single rail type... then the contrast will fall between 5 volts and ground...

I have written the ASM and C code to write to the LCD screen and display messages and user input information..

Code 13

Code:

org 0 ; Reset vector

sjmp Start

org 30H ; Code starts here

Start:

acall LcdInit ; Initialise screen

While:

acall LcdGotoline1

mov DPTR,#mess1 ; Get message 1

acall LcdPrint

acall LcdGotoline2

mov DPTR,#mess2 ; Get message 2

acall LcdPrint

mov A,#0CDH ; Line 2 position 13

acall LcdCmd

jb P0.0, SW2 ; Is switch one pressed

mov A,#31H ; print a '1'

acall LcdData

SW2:

jb P0.1,NS ; Is switch two pressed

mov A,#32H ; print a '2'

acall LcdData

NS:

sjmp While ; Back to loop

; Screen Init..

;---------------

LcdInit:

clr P3.6

clr P3.7

acall Delay15 ; Settle time

mov P1,#33H ; Init 1

setb P3.5

nop

clr P3.5 ; Init 2

acall Delay5

setb P3.5

nop

clr P3.5

acall Delay1

mov A,#38H ; Function set 38

acall LcdCmd

mov A,#0CH ; Display on

acall LcdCmd

mov A,#06H ; cursor off

acall LcdCmd

mov A,#01H ; Clear and home..

acall LcdCmd

ret

; Screen goto

;---------------

LcdGotoline1:

mov A,#080H ; Home 0,0

acall LcdCmd

ret

LcdGotoline2:

mov A,#0C0H ; Home 0,1

acall LcdCmd

ret

; Screen Print

;---------------

LcdPrint:

clr A

Lp:

push Acc ; save index

movc A,@A+DPTR ; Get character

jz Fin ; NULL terminator

acall LcdData ; place on screen

pop Acc

inc A ; Increase index

sjmp Lp ; Next character

Fin:

pop Acc

ret ; Done

; Screen Busy

;---------------

LcdBusy:

mov P1,#0FFH ; Port as input

clr P3.7 ; RS = 1

setb P3.6 ; RW = 0

setb P3.5 ; E on

nop

mov A,P1 ; Busy flag

clr P3.5 ; E off

clr P3.6 ; RW = off

ret

; Screen data

;---------------

LcdData:

push Acc ; save data

Dbusy:

acall LcdBusy ; See if screen is ready

jb Acc.7,DBusy ; Loop until it is

pop Acc ; get data

setb P3.7 ; RS = 1

clr P3.6 ; RW = 0

mov P1,A ; Data to screen

setb P3.5 ; E on

nop

clr P3.5 ; E off

clr P3.7 ; RS = off

ret

; Screen command

;---------------

LcdCmd:

push Acc ; save data

Cbusy:

acall LcdBusy ; See if screen is ready

jb Acc.7,CBusy ; Loop until it is

pop Acc ; get data

clr P3.7 ; RS = 0

clr P3.6 ; RW = 0

mov P1,A ; Command to screen

setb P3.5 ; E on

nop

clr P3.5 ; E off

ret

delay15:

mov R2,#1BH ; Aproximately 15mS

sjmp delay

Delay5:

mov R2,#0AH ; aproximately 5mS

sjmp delay

Delay1:

mov R2,#2H ; Aproximately 1mS

delay:

mov R1,#0 ; 2 clock cycles (loading) = 2

d1:

djnz R1,d1 ; 2 * 256 clock cycles *180 = 92160

djnz R2,d1 ; 2 * 180 clock cycles = 380

ret ; 2 clock cycles (return) = 2

; * 1.0815 (11.0952 osc) = 100.07ms

Mess1: db " PRESS A KEY ",0

Mess2: db "YOU PRESSED: ",0

ENDFrom the code above you will see that all the commands are made by manipulating the data and control lines ( buses ). By writing several low level “device drivers” then several High level routines, we have proper control over the device connected to port 1

LcdPrint can be called to print an entire NULL terminated string to the display.. Almost automating the process.

The C code version starts to show the big differences when programming.... We can use strings as simply as typing them out.. If you examine the differences in the code, you start to understand the ease without the mundane programming.... I do not want to discourage ASM coding as its the nuts and bolts that all compilers are built on....

I program comfortably in both environments so I can get to grips with both... I have written oodles of line of code in ASM and in C.. You can include ASM into C code to make the timing aspect of ASM possible in C...

Here's my representation of the code in C.... Representation because the code WILL start to differ greatly..

Code 14

C:

#include<8051.h> // definition file

#define LCDPORT P1

__sbit __at (0xB7) RS; // Register select pin

__sbit __at (0xB6) RW; // Read write pin

__sbit __at (0xB5) E; // Enable pin

void delayUs(int x)

{ // As I don't need uS delays:----

x/=19; // Explanation: This takes 380uS

while(x--); // This takes 11uS 1000 / 19 = 52.

} // 52 * 11uS + 380uS + 4uS = 963uS

void delayMs(int x)

{

while(x--)

delayUs(1000); // 13uS + 963uS = 976uS (close enough )

}

unsigned char LcdBusy(void)

{

char ERR = 0;

LCDPORT = 0xFF; // Port as input

RS = 0; // Set for command

RW = 1; // Set to read

E = 1; // Clock on

ERR = LCDPORT & 0x80; // Bit 7 is busy flag

E = 0; // Clock off

RW = 0; // Set to write

if(ERR)return 1; // Return 1 or 0

return 0;

}

void LcdCmd( unsigned char C)

{

while(LcdBusy()); // Wait until not busy

RS = 0; // Set to command

RW = 0; // Set to write

LCDPORT = C; // Write command

E = 1; // Clock

E = 0;

}

void LcdData( unsigned char C)

{

while(LcdBusy()); // Wait until not busy

RS = 1; // Set to Data

RW = 0; // Set to write

LCDPORT = C; // Write Data

E = 1; // Clock

E = 0;

}

void LcdInit(void)

{

delayMs(50); // Setting time

RS = 0; // Command

RW = 0; // Write

LCDPORT = 0x33; // Init value

E = 1; // Clock

E = 0;

delayMs(15); // Twice

E = 1; // Clock

E = 0;

delayMs(5); // Ready to start

LcdCmd(0x38); // Function set

LcdCmd(0x0C); // Display command

LcdCmd(0x06); // Cursor conmmand

LcdCmd(0x01); // Clear and Home command

}

void LcdClear(void)

{

LcdCmd(1); // Clear and Home

}

void LcdPrintRam(unsigned char* str)

{

while(*str != 0)

LcdData(*str++); // Print until NULL

}

void LcdPrintConst( const char * str)

{

LcdPrintRam((unsigned char *) str); //Convert to ram and print

}

void LcdGoto(unsigned char x, unsigned char y)

{

x += 0x80; // Line 1

if(y==1) x+=0x40; // Line 2

LcdCmd(x); // Line Command

} // For 4 line use 0xD4 and 0x94 as well..

void main(void) // Main entry point

{

LcdInit(); // Get screen ready

while(1) // Forever loop

{

LcdGoto(0,0);

LcdPrintConst(" PRESS A KEY ");

LcdGoto(0,1);

LcdPrintConst("YOU PRESSED: ");

LcdGoto(13,1);

if(!P0_0) LcdData(0x31);

if(!P0_1) LcdData(0x32);

}

}I am hopefully going to upload the serial communication tutorial next. Simple micro ~ PC stuff....

Enjoy!