I purchased a Geeetech Aluminium Prusa i3 a few months before Christmas 2017, mainly because I wanted to be able to produce a quick mock-up for any idea that I had regarding non off-the-shelf items that can be made, without spending a whole heap of time cutting/filing/welding/machining metal parts.

I have a couple of CNC machine projects currently in-progress and some other ideas, where I will likely need to make custom parts.

A 3D printer is perfect for this, as you can have a physical object in your hands in a few hours, that is produced virtually unattended.

As most people who start out with 3D printers do, I have been making upgrades for the machine itself and items on the Honeydo list, along with a few trinkets just to test out print quality etc.

I'm currently only printing in PLA plastic, as I need to upgrade the PSU, add a MOSFET for the heated bed and build an enclosure, so I can print ABS without stinking out my workshop and/or causing any health concerns.

For part design, I am using Autodesk Fusion 360 and exporting the STL model to Repetier Host.

From Repetier Host, I am using Slic3r PE to produce the G-Code and printing parts solely off the SD card.

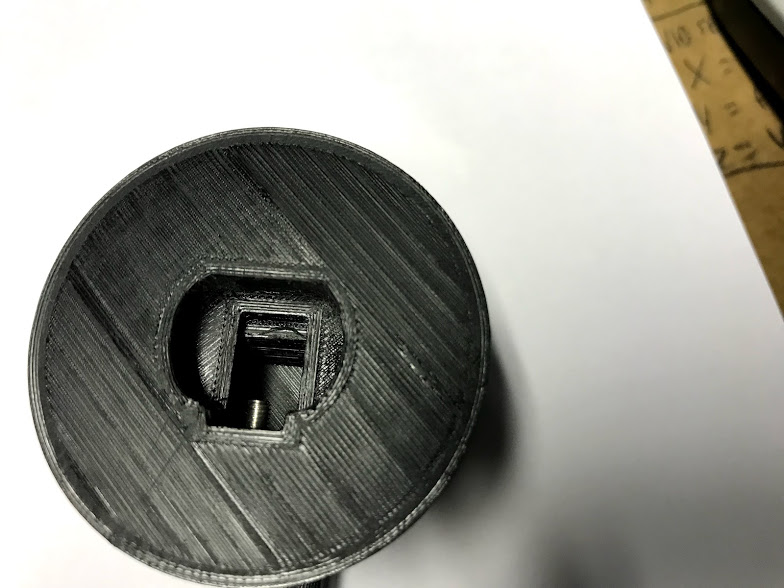

Our shower handle fell off (twice) when my wife was using it and no replacement part could be found locally.

An hour or so with Fusion 360 and about 4 hours printing produced the following, which has pleased her no end:

I have a couple of CNC machine projects currently in-progress and some other ideas, where I will likely need to make custom parts.

A 3D printer is perfect for this, as you can have a physical object in your hands in a few hours, that is produced virtually unattended.

As most people who start out with 3D printers do, I have been making upgrades for the machine itself and items on the Honeydo list, along with a few trinkets just to test out print quality etc.

I'm currently only printing in PLA plastic, as I need to upgrade the PSU, add a MOSFET for the heated bed and build an enclosure, so I can print ABS without stinking out my workshop and/or causing any health concerns.

For part design, I am using Autodesk Fusion 360 and exporting the STL model to Repetier Host.

From Repetier Host, I am using Slic3r PE to produce the G-Code and printing parts solely off the SD card.

Our shower handle fell off (twice) when my wife was using it and no replacement part could be found locally.

An hour or so with Fusion 360 and about 4 hours printing produced the following, which has pleased her no end: