Split off from this thread:

JimB said:

Western asked:

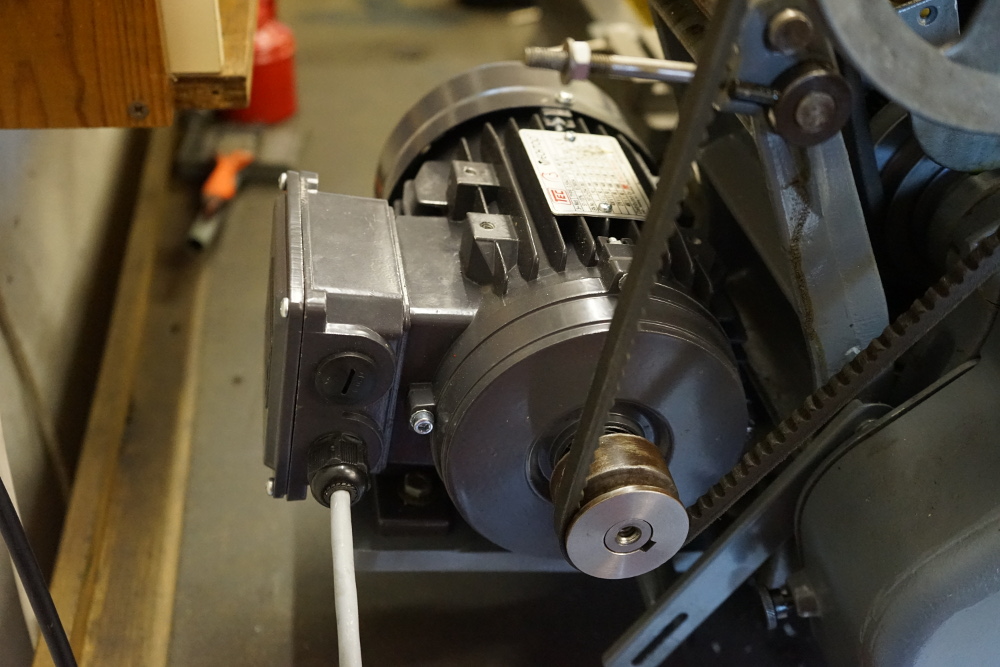

The new motor is rated at 0.55kW (0.75HP), compared with the original motor which was rated at 0.25HP.

The new motor:

The old motor and home made Start/Stop/Reverse controller box

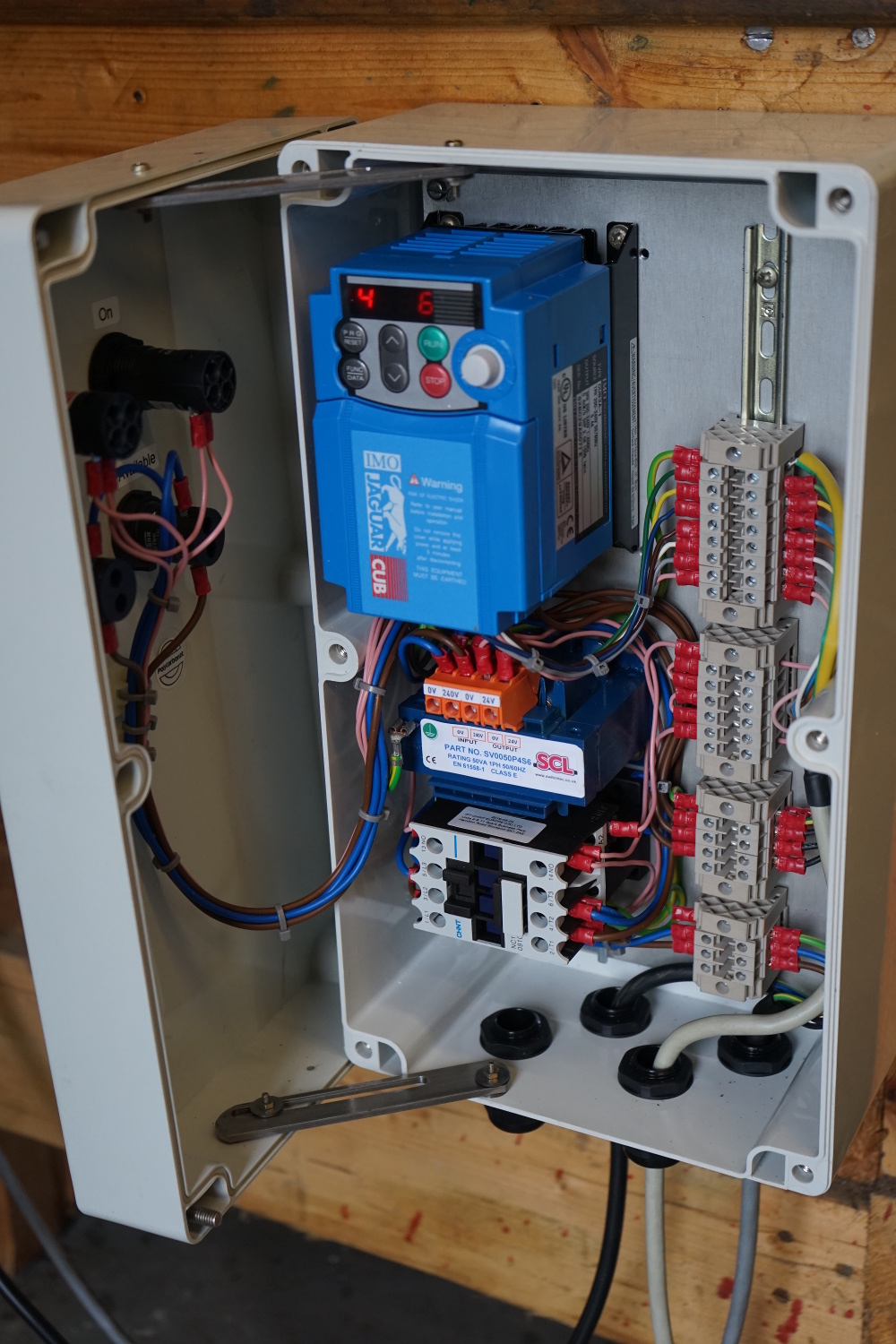

The VFD is a Jaguar Cub.

It came as a bare module suitable for mounting in a control cabinet.

Rather than just having it fixed to the end of the bench and prone to invasion by swarf and spiders, I built it into an enclosure as shown here:

The extra transformer and contactor is so that I can implement some kind of emergency stop kick-bar for when things go pear shaped.

I must get on and do that, it is nearly a year since I built this thing.

Also, using an enclosure like that allows the use of reasonable terminals for the "field cables".

The overall view, this picture was taken before I fitted some cable trunking to tidy up the field cables which connect the system together, and fitted the guard back on the drive belt and countershaft pulley.

The incoming supply to all this is the normal 240v single phase domestic mains.

JimB

Tesla coil progress

How is three phase different than just adding the frequency? Single phase "pulses"; the voltage drops to zero twice per AC cycle. Three phase is totally balanced, you can draw the same amount of power all the way through the AC cycle, with suitable loads. It also inherently has a rotation...

www.electro-tech-online.com

JimB said:

I have a small lathe, a Myford ML7 which is nearly as old as I am.

A year or so ago I replaced the old single phase motor with a three phase motor and three phase variable frequency drive.

Western asked:

What size is the motor Jim and what sort of VFD are you using. I'm assuming you run it off single phase still??

The new motor is rated at 0.55kW (0.75HP), compared with the original motor which was rated at 0.25HP.

The new motor:

The old motor and home made Start/Stop/Reverse controller box

The VFD is a Jaguar Cub.

It came as a bare module suitable for mounting in a control cabinet.

Rather than just having it fixed to the end of the bench and prone to invasion by swarf and spiders, I built it into an enclosure as shown here:

The extra transformer and contactor is so that I can implement some kind of emergency stop kick-bar for when things go pear shaped.

I must get on and do that, it is nearly a year since I built this thing.

Also, using an enclosure like that allows the use of reasonable terminals for the "field cables".

The overall view, this picture was taken before I fitted some cable trunking to tidy up the field cables which connect the system together, and fitted the guard back on the drive belt and countershaft pulley.

The incoming supply to all this is the normal 240v single phase domestic mains.

JimB