Hello everyone,

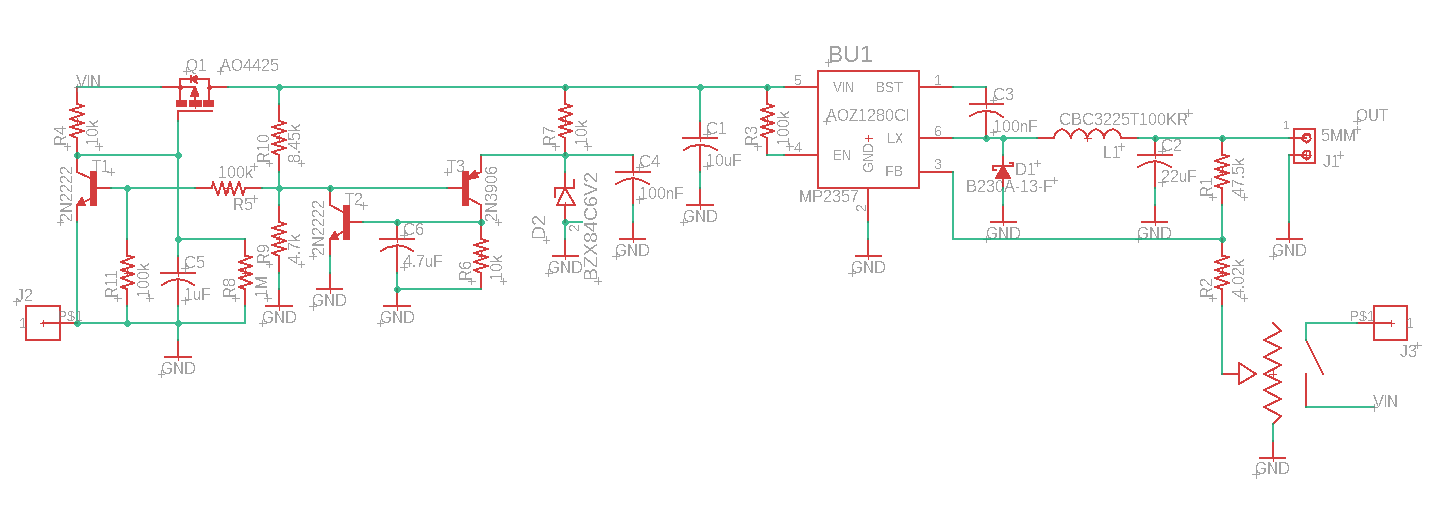

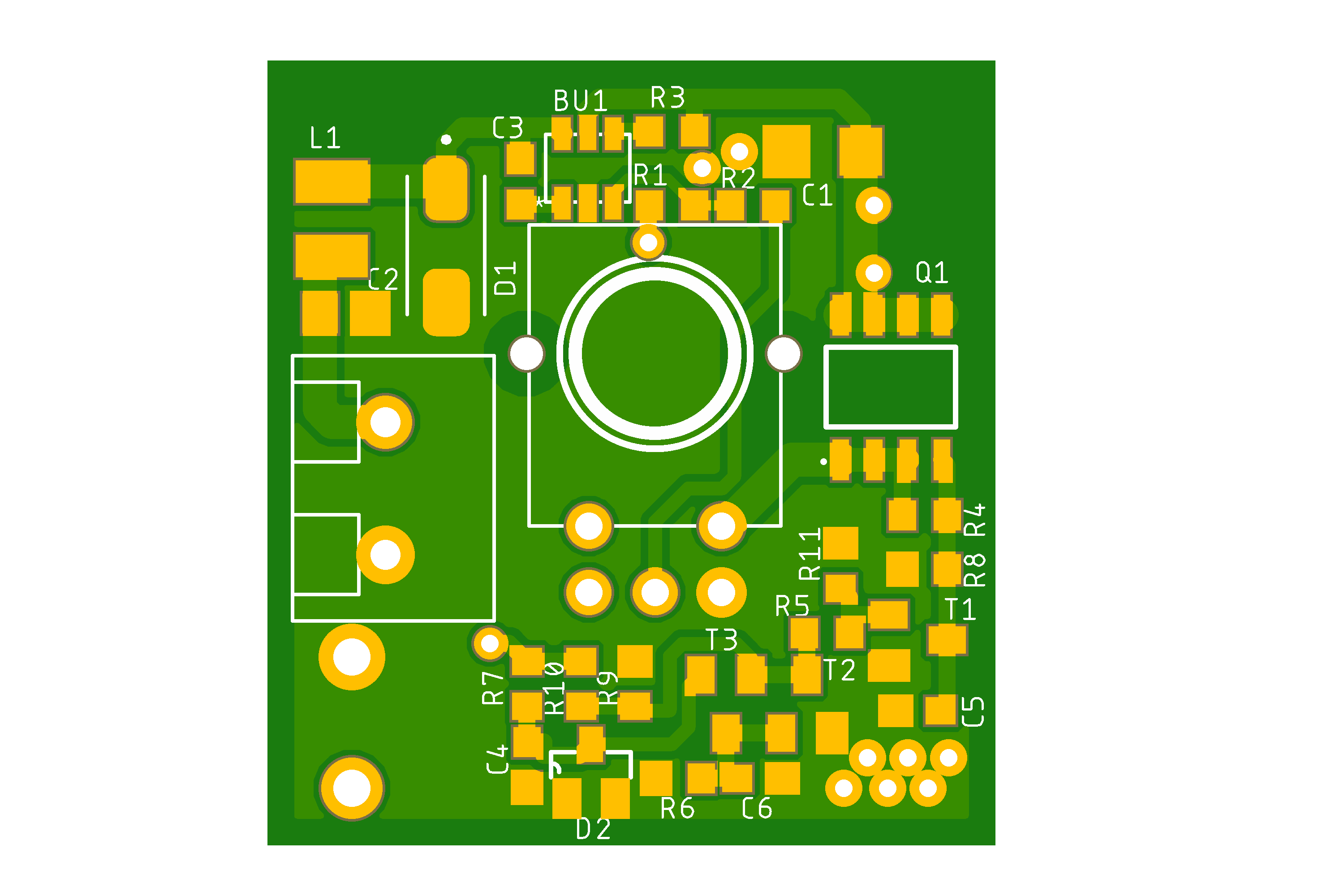

I have attached a snip image of a design I am using and have been using for almost a year and a half now...

Here is the story on the board.

(Jump down to circuit explanation if you want)

Last year, I made a few hundred using the MP2357 regulator, but since it went out of stock, I switched to the AOZ1280CI, and made about 2000 pieces last year, with a different board layout.

The schematic looked identical to the one attached, I was just using a WH148 style PCB mount right angle potentiometer with the detent and everything...

Then this year, I switched to a higher quality upright PCB mount potentiometer, and kept all the other same components...

I made 460 pieces of this exact board in the course of 3 batches, and the success rate was almost 100%, 1 got shorted out and blew up, and 1 other one did not shut off, but 458 working out of 460 is what I would call pretty good.

Then, I hired another worker, jumped into this board, wanting to get a lot of stock made, so I did the rest of those 1000 boards(540 pieces) all in one batch.

I had him test the boards one at a time for the correct output voltages(Variable from 5V to 10V with the potentiometer) and we just had the input voltage set at 16.5V.

The testing procedure went as follows....

1. Power up the board with 16.5V

2. Turn the detent on and make sure the output is 5V and the load runs(load is a very small fan)

3. Turn the potentiometer to maximum and make sure the output is 10V.

4. Turn the input voltage down to 15.7V and make sure the board shuts off.

5. Turn the input up to 16.5V and power cycle, making sure it restarts.

All of the boards passed our testing, so I sent them to be assembled onto the fans.

When they tested the fans, about 1 in 4 worked, and the rest of the boards had the AOZ1280CI blown!!!

After some testing, the ones that blow all work at 16.5V and 17V but as soon as you get to the 19V and 20V range, about one in four blow up when you start them up!

All of the previous boards were tested with the same inputs, and 3000 have been in use for more than 6 months, and no problems so far....

The only explanation I can come up with is something in the assembly process....

Like could the oven temperature too high(I had boosted it a little because of older solder paste) be an issue?

Any other ideas?

Circuit Explanation -

The input source is about a 15V Min 20.5V Max 18V nominal lithium ion cordless tool battery(DeWalt, Makita, Milwaukee, etc.)

The power comes into the circuit board into J3, goes through the potentiometer detent(for complete power cutoff when the detent is switched off) and then goes to the net called VIN.

VIN goes through Q1 for low voltage protection, then to the input of the regulator circuit.

The feedback of the regulator is adjustable with the potentiometer for variable speed on the fan.

The 6.2V Zener diode(D2) and the resistor divider(R10/R9) sets the low voltage cutoff's protection point to about 15.9V.

The T2/T3 latch makes the cutoff stay off when activated, until power is cycled, and C6 holds the latch open for startup, but anyway, I'm not worried about the low voltage part, the only thing you need to know is that it works and is quite reliable.

The trouble starts at the input of the regulator(I know this because when testing, I shorted the source and drain of Q1 and got the same results)

I took a blown board, removed C1, C2, C3, L1, and D1, and they are all still functional, it blew just the regulator...

I also tested multiple with Q1 shorted, so it has nothing to do with the low voltage shutoff part of it....

I have attached a snip image of a design I am using and have been using for almost a year and a half now...

Here is the story on the board.

(Jump down to circuit explanation if you want)

Last year, I made a few hundred using the MP2357 regulator, but since it went out of stock, I switched to the AOZ1280CI, and made about 2000 pieces last year, with a different board layout.

The schematic looked identical to the one attached, I was just using a WH148 style PCB mount right angle potentiometer with the detent and everything...

Then this year, I switched to a higher quality upright PCB mount potentiometer, and kept all the other same components...

I made 460 pieces of this exact board in the course of 3 batches, and the success rate was almost 100%, 1 got shorted out and blew up, and 1 other one did not shut off, but 458 working out of 460 is what I would call pretty good.

Then, I hired another worker, jumped into this board, wanting to get a lot of stock made, so I did the rest of those 1000 boards(540 pieces) all in one batch.

I had him test the boards one at a time for the correct output voltages(Variable from 5V to 10V with the potentiometer) and we just had the input voltage set at 16.5V.

The testing procedure went as follows....

1. Power up the board with 16.5V

2. Turn the detent on and make sure the output is 5V and the load runs(load is a very small fan)

3. Turn the potentiometer to maximum and make sure the output is 10V.

4. Turn the input voltage down to 15.7V and make sure the board shuts off.

5. Turn the input up to 16.5V and power cycle, making sure it restarts.

All of the boards passed our testing, so I sent them to be assembled onto the fans.

When they tested the fans, about 1 in 4 worked, and the rest of the boards had the AOZ1280CI blown!!!

After some testing, the ones that blow all work at 16.5V and 17V but as soon as you get to the 19V and 20V range, about one in four blow up when you start them up!

All of the previous boards were tested with the same inputs, and 3000 have been in use for more than 6 months, and no problems so far....

The only explanation I can come up with is something in the assembly process....

Like could the oven temperature too high(I had boosted it a little because of older solder paste) be an issue?

Any other ideas?

Circuit Explanation -

The input source is about a 15V Min 20.5V Max 18V nominal lithium ion cordless tool battery(DeWalt, Makita, Milwaukee, etc.)

The power comes into the circuit board into J3, goes through the potentiometer detent(for complete power cutoff when the detent is switched off) and then goes to the net called VIN.

VIN goes through Q1 for low voltage protection, then to the input of the regulator circuit.

The feedback of the regulator is adjustable with the potentiometer for variable speed on the fan.

The 6.2V Zener diode(D2) and the resistor divider(R10/R9) sets the low voltage cutoff's protection point to about 15.9V.

The T2/T3 latch makes the cutoff stay off when activated, until power is cycled, and C6 holds the latch open for startup, but anyway, I'm not worried about the low voltage part, the only thing you need to know is that it works and is quite reliable.

The trouble starts at the input of the regulator(I know this because when testing, I shorted the source and drain of Q1 and got the same results)

I took a blown board, removed C1, C2, C3, L1, and D1, and they are all still functional, it blew just the regulator...

I also tested multiple with Q1 shorted, so it has nothing to do with the low voltage shutoff part of it....