Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

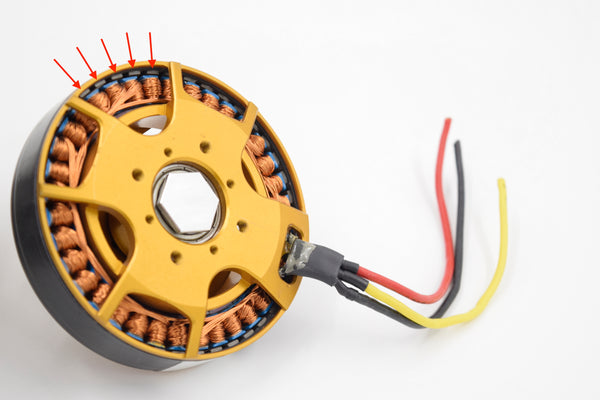

Many BLDC motors have 3-phase drive. If they had more pole pairs that would not work.What three? I do not understand.

I would like to ask what is the ratio of rotor and stator pole pairs of BLDC motors in general?

www.tytorobotics.com

www.tytorobotics.com

www.tytorobotics.com

www.tytorobotics.com

Not in my experience, BLDC generally have more torque than it 3ph counterpart for the same frame size, the motors are identical, as I have converted both to the other format. BLDC is a DC brushed motor turned inside out.[Sorry Max, but anything only driving two windings is using a cut-down or economy setup - most serious systems run all three phases; even the basic PIC BLDC stuff Microchip provide libraries for and like on the dev board is full three phase PWM.