tommyflynn

New Member

Hi,

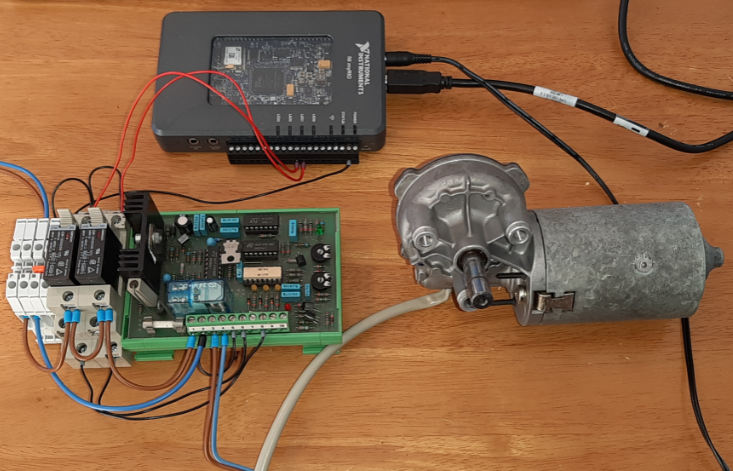

I am looking for help with the wiring involved with controlling the speed of a motor on LabVIEW through a PC rather than changing it manually on my motor control card. I currently have the motor running in both CW and ACW directions using LabVIEW.

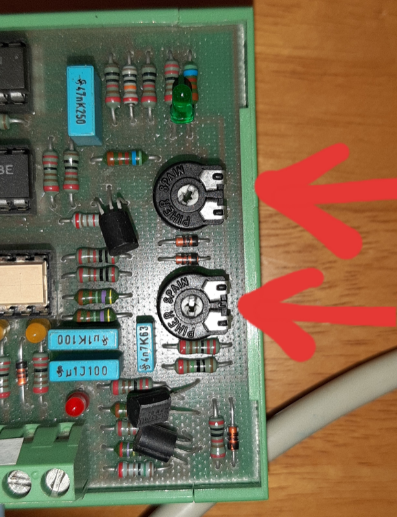

I know I must desolder the potentiometers on my motor control card (How I currently can control motor speed) and connect this to my NI myRIO device. I feel I know how to configure the LabVIEW code (slider/dial output) but require some help with the wiring.

I have attached a couple of photos.

I am looking for help with the wiring involved with controlling the speed of a motor on LabVIEW through a PC rather than changing it manually on my motor control card. I currently have the motor running in both CW and ACW directions using LabVIEW.

I know I must desolder the potentiometers on my motor control card (How I currently can control motor speed) and connect this to my NI myRIO device. I feel I know how to configure the LabVIEW code (slider/dial output) but require some help with the wiring.

I have attached a couple of photos.