Hi There!

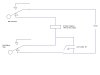

I have been tasked by my boss to use two tethered float switches having three leads to control a basement sump pump. He claims one needs to be placed halfway ,with the other at the bottom of the well.I am having a hard time designing a simple circuit to control the pump,using a 3phase contactor.The object of using two switches is to prevent pump from fluttering ON/OFF every second.

I have been tasked by my boss to use two tethered float switches having three leads to control a basement sump pump. He claims one needs to be placed halfway ,with the other at the bottom of the well.I am having a hard time designing a simple circuit to control the pump,using a 3phase contactor.The object of using two switches is to prevent pump from fluttering ON/OFF every second.

Last edited: