technogeek

New Member

Hi guys,

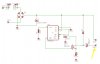

As you probably remember, I'm trying to build a mains powered switcher power supply... Well, I got it to work... sorta.

I made the values for the components for a 60V @0.7A LED bank... Now these should work for a 16V @o.7A bank, right? Here's what happens...

Powers on, and there's a high pitched whine. 100khz shouldn't be heard!! Anyways, the LED's light, which is a good sign. I check the current through them, and it shows 0.3A.

WORSE, when I touch the "negative" lead (the one coming off the inductor), the LED's brighten and the current rises to 0.4A. Meanwhile the pitch of the hum changes in frequency...

What did i do wrong? This can't be normal! Granted, the inductor is larger than it should be for just 6 LEDs, but I didn't think that would be a problem? And what's with the touch sensitivity!?!

In need of some switcher expertise..........................

As you probably remember, I'm trying to build a mains powered switcher power supply... Well, I got it to work... sorta.

I made the values for the components for a 60V @0.7A LED bank... Now these should work for a 16V @o.7A bank, right? Here's what happens...

Powers on, and there's a high pitched whine. 100khz shouldn't be heard!! Anyways, the LED's light, which is a good sign. I check the current through them, and it shows 0.3A.

WORSE, when I touch the "negative" lead (the one coming off the inductor), the LED's brighten and the current rises to 0.4A. Meanwhile the pitch of the hum changes in frequency...

What did i do wrong? This can't be normal! Granted, the inductor is larger than it should be for just 6 LEDs, but I didn't think that would be a problem? And what's with the touch sensitivity!?!

In need of some switcher expertise..........................