My Kemppi welder needs repair.

I'm not really that experienced with electronics, but have worked on it before. Just need some guidance

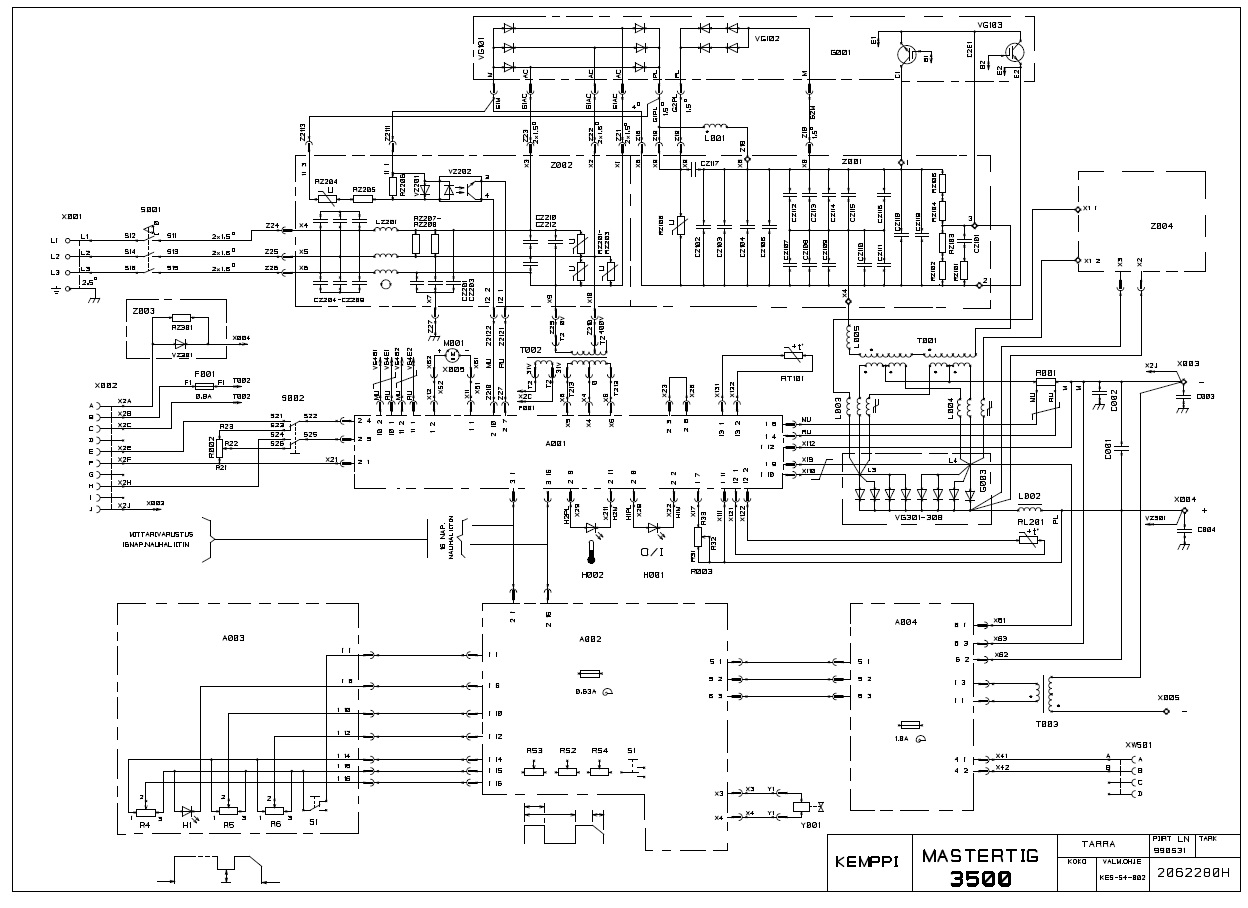

The HF tig function suddenly stopped working, but scratch tig worked.

After inspecting the unit I could see that a wire going to a diode was burned off, so I think I need to just swap this diode.

**broken link removed**

The diode is marked with 9750144. Google didnt show any results for this.

Talked to Kemppi service and they said they no longer manufacture these diodes, so they could not help me. They did give me some information though.

The diodes are used on the secondary rectifier. They could only say it is a very fast 60-70A / 600V diode. But no spec on how fast.

They said I could try to swap the diode if i find a similar, but that it probably would not work due to the current passing through would need to be exactly the same on all the diodes, if not they will burn up. Apparently kemppi has some super diode testing and sorting machine for this.. I don't

So my question is.. There are 8 diodes. Looks like there are 2 sets with 4 diodes each going to a bus of some sort?

Can I just swap the 4 diodes going to the same bus, or do I need to swap all 8?

Do you think it is possible at all to swap the diodes and make it work?

Any other things I should check?

I found these on ebay: **broken link removed**

PDF with specs attached to message below.

Regards

Dan

I'm not really that experienced with electronics, but have worked on it before. Just need some guidance

The HF tig function suddenly stopped working, but scratch tig worked.

After inspecting the unit I could see that a wire going to a diode was burned off, so I think I need to just swap this diode.

**broken link removed**

The diode is marked with 9750144. Google didnt show any results for this.

Talked to Kemppi service and they said they no longer manufacture these diodes, so they could not help me. They did give me some information though.

The diodes are used on the secondary rectifier. They could only say it is a very fast 60-70A / 600V diode. But no spec on how fast.

They said I could try to swap the diode if i find a similar, but that it probably would not work due to the current passing through would need to be exactly the same on all the diodes, if not they will burn up. Apparently kemppi has some super diode testing and sorting machine for this.. I don't

So my question is.. There are 8 diodes. Looks like there are 2 sets with 4 diodes each going to a bus of some sort?

Can I just swap the 4 diodes going to the same bus, or do I need to swap all 8?

Do you think it is possible at all to swap the diodes and make it work?

Any other things I should check?

I found these on ebay: **broken link removed**

PDF with specs attached to message below.

Regards

Dan