case-sensitive

Member

Hello,

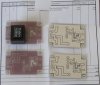

this is meant to be a crossover for an amplifier project. I heard ground is meant to refer/lead to a single point. Tried hard but its just too much going on on the board. Is my layout ok so far (see pictures)

board, ground put on top layer so its easier to see

**broken link removed**

schematic, ground shown dotted

**broken link removed**

Cheers,

Case

this is meant to be a crossover for an amplifier project. I heard ground is meant to refer/lead to a single point. Tried hard but its just too much going on on the board. Is my layout ok so far (see pictures)

board, ground put on top layer so its easier to see

**broken link removed**

schematic, ground shown dotted

**broken link removed**

Cheers,

Case