draculic acid69

Member

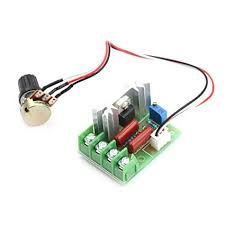

Ok so I brought a thyristor circuit motor control governor to use in a heating mantle with a nichrome element and upon turning it on I found that even with the potentiometer on the thyristor turned all the way off down to zero it still let's enough current thru to

Have the element get to 190'c and as I want a finer control this is unacceptable.now the lucky part is I have two of these so I was wondering if I can turn it down to zero and then put the reduced output from this into the input of the second thyristor circuit and use the second ones potentiometer to try and get a fine control of the temperature.is there anything wrong with this idea? below is a pic of the $3 thyristor circuit I'm talking about.there all over eBay for a few bucks and the two I have are from different sellers and are similar.im not sure if the problem is bcoz of the thyristor circuit allowing that much current thru even when turned down to zero or whether that's meant to happen.what I want to know is am I going to damage the circuits putting them back to back or am I going to be pleased that it works fine?

Have the element get to 190'c and as I want a finer control this is unacceptable.now the lucky part is I have two of these so I was wondering if I can turn it down to zero and then put the reduced output from this into the input of the second thyristor circuit and use the second ones potentiometer to try and get a fine control of the temperature.is there anything wrong with this idea? below is a pic of the $3 thyristor circuit I'm talking about.there all over eBay for a few bucks and the two I have are from different sellers and are similar.im not sure if the problem is bcoz of the thyristor circuit allowing that much current thru even when turned down to zero or whether that's meant to happen.what I want to know is am I going to damage the circuits putting them back to back or am I going to be pleased that it works fine?