Very interesting problem you stated here. This is actually a somewhat complicated control system problem.Let's do another case. This time the pulley is already rotating with angular velocity, ω, of 2π rad/s. There is no angular acceleration which means torque is zero and if we further assume that there is no friction involved then the rocket isn't really doing any work; it's basically in off mode.

The setup looks like this. But this time as I mentioned above the pulley was already rotating at a constant angular velocity of 2π rad/s which translates to linear velocity of 2π m/s when the rope which has 2 kg mass suspended to it and resting on ground gets somehow attached to it. The vertical height between the pulley and ground could be approximated to be 20 meters.

Our purpose is to lift the mass to some height above the ground and we also want to keep things as calm as they could be; I mean no jerky motion.

We can assume that the rocket has some kind of a sensor which regulates the angular velocity at 2π rad/s. It turns the rocket on if the velocity is under 2π rad/s and off if it goes above. Further, we can also assume that the sensor makes rocket to exert different amount of force as required.

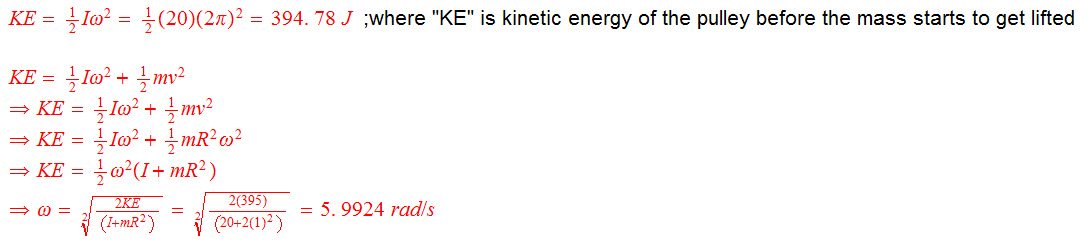

As soon as the rope gets attached to the pulley, the angular velocity of pulley will go down for an infinitesimal amount of time and during that time both pulley and mass would have same speed.

Then, instantly, the rocket turns on and starts exerting force. The rocket aims to get the system to 2π rad/s within 1 second. Therefore the system needs the acceleration of (2π-5. 9924)/1s=0.291 rad/s/s for one second. This time we need to know rocket force and I believe that the formula derived by you can be used, α=( R Ft - R m g )/ ( I + m R^2). After rearranging Ft={α/(R(I+mR^2))}+mg={0.291/(20+2)}+2(10)=20.013 N. Once the system has reached 2π rad/s angular velocity then the rocket just has to exert 20 N force to counterbalance the clockwise torque to 2 kg mass. Do you agree with everything I have said?

I think I agree with just about everything you said. I'll need to read through it again with a fresh mind later to be sure. There are a few nit-picky things I can say.

First, I would say that your statement "... As soon as the rope gets attached to the pulley, the angular velocity of pulley will go down for an infinitesimal amount of time and during that time both pulley and mass would have same speed ..." is not quite correct. I might say that "once the pulley is connected to the mass by the rope, the pulley will decelerate for a short amount of time and during this time, the mass will accelerate. Eventually, both speeds will converge and stabilize to one value".

Second, the value of the acceleration you calculated to get to the correct speed in one second, while perhaps correct in value (note that I didn't check to see if you got it right), represents a very simplified answer that could be considered an average target value for the control system. A real control system would not be able to achieve this exact acceleration profile (basically a step profile you specified).

A real problem like this would need to consider the stretch, spring force and damping of the rope, the dynamic response of the rocket force and the details of the type of control system used and the gain values used in the feedback design. Design would have to consider stability, robustness and meeting the specifications as you have provided them.

Like I said, this is a very interesting problem, and not trivial. Hence, your answer, though basically correct ( I think), and demonstrative of good thinking on your part, should be viewed as an approximate first pass answer to a problem that is not trivial and one that might have various types of solutions depending on the system parameters and final chosen control system design.

Last edited: