ThomsCircuit

Well-Known Member

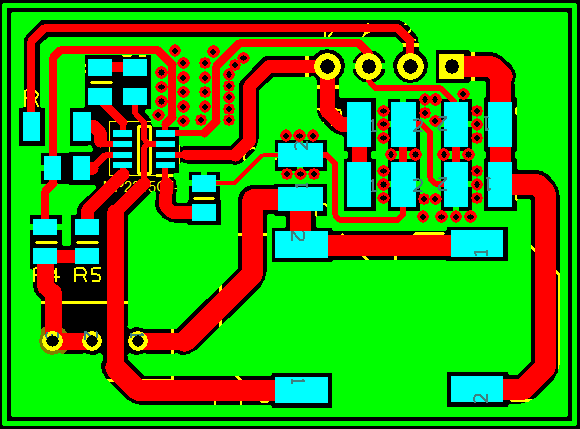

Continuous copper pour.

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

Thanks for the datasheets. As for buying parts from ebay, that's OK as long as you get what you expect. Ebay sellers often don't give you the the part number or data to let you find out the parasitic specs of the part.CDRH104RNP-221NC

CDRH104RT125NP-4R7PC

Its an Ebay seller. I know you guys dont like buying components from here but if you dont care for these i can keep looking

Here is a passage from the author and his use of L2.But L2 is going to be a problem. It's saturation current is only 0.95 Amps. So at 3 amps it's lost it's inductive properties, and will just be a wire with 560 milliOhms of resistance. Which, at 3 amps, will dissipate about 5 Watts of heat.

If the CDRH104RT125NP-4R7PC is not suitable for the application described above i have located CDRH3D16/HPNP-4R7NC. And while i do appreciate your sharing with me what value is important I do not know what im looking at. The original 4.7uh part says 5.57 under saturation current and this new one says 1.20 so I dont know how .95 was calculated. If you could look at this Inductor and tell me what you think.The graph to look at is the DC Bias Characteristics. Notice that at 12 Volts, the part has lost over 80% of it's capacitance. So what should be 22uF, is really less than 5uF. Now, ceramic capacitors can still be used, but you need to chose the parts wisely and compensate for as needed.

So glad you asked. I was trying to explain to my wife that I would never go above 12 volts output but she just gave me a strange glare. So yes. This as designed is capable of 24V input I would apply a max of 15V. And the output range would be 12V to 3.3V. From what i understand the greater the range of input / output (24v in / 5v out) the hotter the inductor gets.What is the highest voltage you want the output to go to? The 200 K pot will let you go to about 24 volts. But you'll need about 27 Volts on the input to do so.

Great! that makes it a bit easier for me to purchase. Thank you. So if im using 4.7uh for L1 L2 it would have no effect on the input/output voltage ranges as L2 is just being used as a noise filter.But, you really don't need that much inductance for the noise filter. The author said that the cutoff frequency of the filter is about 1KHz, which is correct for those values. But the switching frequency for the mp2315 is 500khZ. There is no reason to set the cutoff so low. In this case, I would use the same 4.7uF inductor for L2 as L1. That inductance, with the existing capacitance, has a cutoff frequency of about 15KHz. Still well below the switching frequency.

An alternative to wide tracks is multiple pours bound to nets

Ive highlighted each net in a different color. Shown encapsulating their associated tracks in red.

It does not encapsulate every track but my point is you can do this instead of beefy tracks. Of course where it cannot be done due to constraints the tracks close to the IC have beefed up tracks.

The ground pour is in green and it is continuous. It reaches every pad where ground is needed. The through hole header pin (in green with arrow) is linked to the bottom layer which joins them together. I added 4 ground vias (circled) that are intended to make a better (more even) connection with the bottom ground plane.

The four corner mounting holes are not linked to anything (isolated) so i dont know if these serve or can serve any additional purpose other than to mount the board. If connecting these to a net or ground will improve anything please let me know.

My understanding of pours, tracks, and overall balance is still very weak. I rely heavily on your opinions to help me understand this.

Thank you.

View attachment 136210

It is just so you can see the red track and the pour at the same time. Perhaps if I did this it would be better understood. Now this shows that after production the tracks will be one with the pour. Yes the spokes are 2.5 times larger this shows 10 in size. the new spoke width is 25.However, I'm not clear on the colors other than green. What is the relationship between the wide red trace and the purple pour, for example?

OK. So if possible move C2 closer or add an additional capOn that buck converter, the current in the supply (pin 2), ground (pin 4) and the capacitors between those pins are where the varying current flow.

It's a good idea to keep that path as short as possible. I suggest you move the capacitors closer to the IC, or put a small ceramic capacitor very close to the IC between pins 2 and 4.

That is what I would do.OK. So if possible move C2 closer or add an additional cap

View attachment 136215

Ok...the image is confusing to me but whatever works for you is ok.It is just so you can see the red track and the pour at the same time. Perhaps if I did this it would be better understood. Now this shows that after production the tracks will be one with the pour. Yes the spokes are 2.5 times larger this shows 10 in size. the new spoke width is 25.

BTW. does this image remind you of anything?

Ok this is unfilled. Only the outlines of the separate net pours.Ok...the image is confusing to me but whatever works for you is ok.