talha_tahir

New Member

Hello.

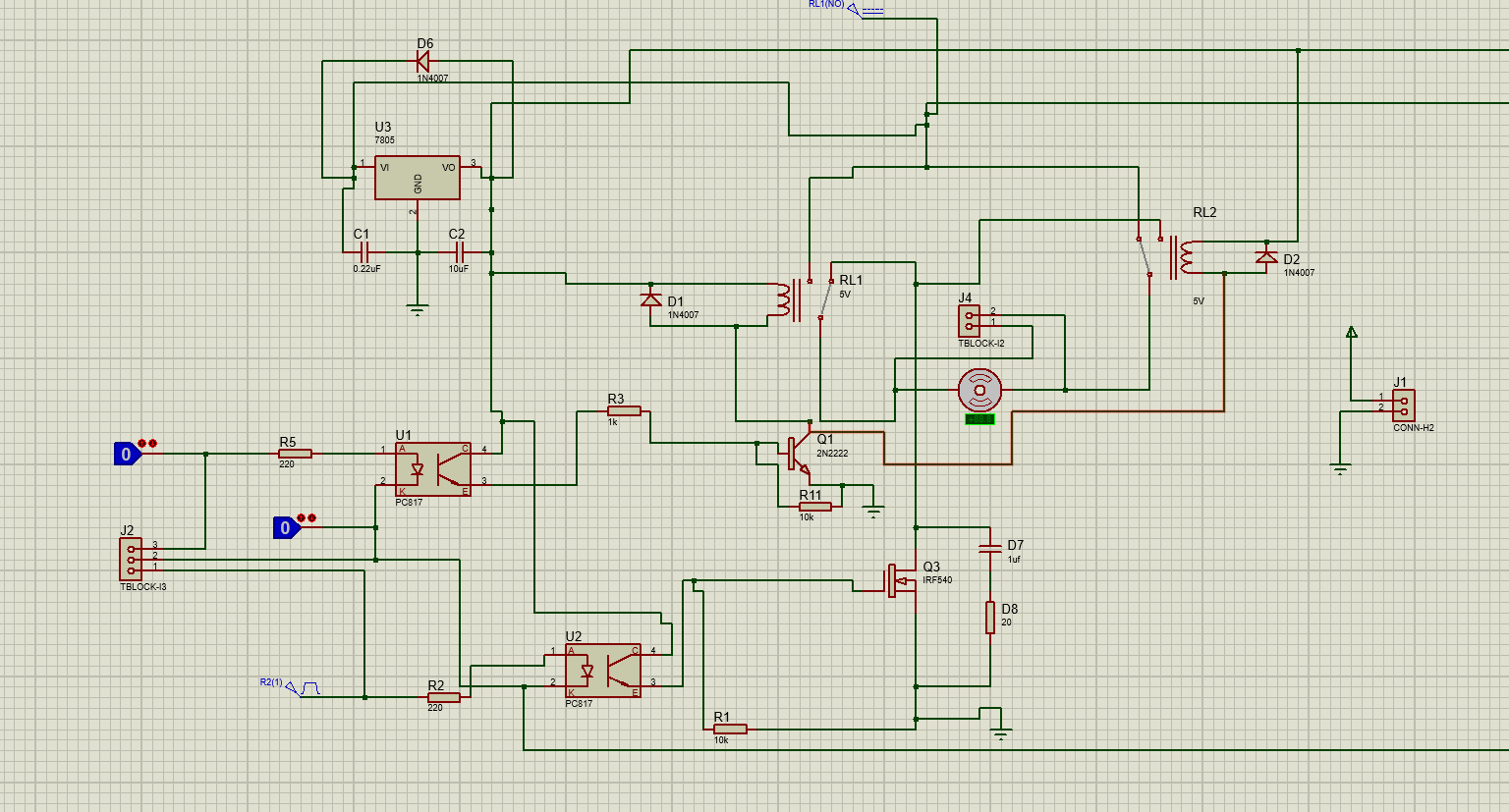

I have created a schematic for a high power dual h bridge utilizing relays and IRF540 Mosfet but i cant seem to calculate the values for the gate resistor to the mosfet plus i would appreciate if anyone could point out any mistakes i made in the design. The schematic is attached below in the zip. The design is for two motors which needs to be PWM'ed , with operating current of about 1.5A No load and Stall current of 14.5 A. This is one side of the h bridge for the full schematic open the zip.

I have created a schematic for a high power dual h bridge utilizing relays and IRF540 Mosfet but i cant seem to calculate the values for the gate resistor to the mosfet plus i would appreciate if anyone could point out any mistakes i made in the design. The schematic is attached below in the zip. The design is for two motors which needs to be PWM'ed , with operating current of about 1.5A No load and Stall current of 14.5 A. This is one side of the h bridge for the full schematic open the zip.

Attachments

Last edited: