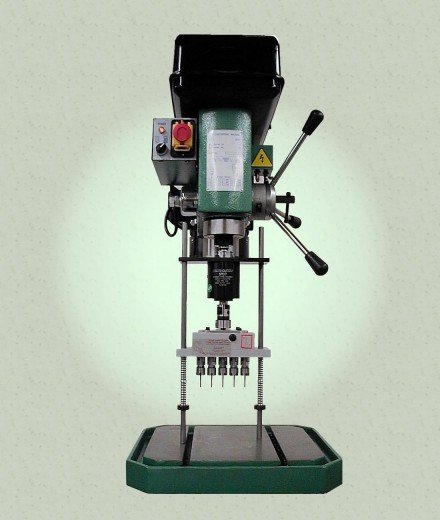

Search for gang drills & multi-spindle drills.

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

If you look at the table in this dc motor description, it says 160mA current, when 24V supply is connected. Wouldn't that be enough for this project's purpose?That might cope with one chuck, but even then it would drill very slowly.

A typical power drill is rated at a few hundred Watts, so I don't think a 24V 10A supply would be enough, particularly bearing in mind that ratings for some online products tend to be 'optimistic' (to put it politely).

Btw, why are these so cheap?

Factory workers make very little money No unions,.Btw, why are these so cheap?

If you look at the table in this dc motor description, it says 160mA current, when 24V supply is connected. Wouldn't that be enough for this project's purpose?

And how big of a amperage power supply should I then get? If one motor has 160mA, then sure 10A supply is enough isn't it?

https://www.banggood.com/775-Gear-M...tail-top-buytogether-auto__2&cur_warehouse=CN

Max speed for drilling wood:

0 to 1/4 inch 3800 to 4000 RPM

1/4 to 1/2 inch 3100 to 3800 RPM

from specs 3500 RPM obtained with a 12 V supply pulling 0.14 amps or 1.68 Watt.

To put this in prospective, 1/8 horsepower is 95 Watts.

How does "Bosch 18V can draw 10 amps" equate to 180 amps? I know, I know you meant to say 180 Watts - to error is human ... .3500 RPM with no load would likely be 0.14 amps. Now, if I tell you the type of bit, bit diameter, the feed rate and the type of wood, can you also tell us the current draw. For example, my Bosch 18V can draw 10 amps from a lithium battery when I use a quarter inch bit into a wet railroad tie feeding about 3 mm per second with a twist bit. That is 180 amps. 1/4 HP.

Where does the spec sheet specify the current rating is "no load"; additional, of what value is a

"no load" rating?

I'll be using 6 of these motors, so if they are connected to 24V one motor draws 0.16A, then 5x0.16=0.8A with a deviation of a few Amperes.

Most power supplies similar to that have a trimmer which you adjust to set the output voltage. The higher the voltage, the lower the maximum current the supply can provide. If you know the power (Wattage) of the supply you can calculate the available current by dividing the power rating by the output voltage. That said, it is not a good idea to draw the maximum rated power from a power supply of unknown quality. Go for 70-80% of the rated power. I agree with Nigel's assessment of that specific supply.if power supply has for example output voltage 9-40V, does this mean that if I buy the motors (link), where voltage is 12-36V, that power station will fry the motors with full voltage or does it regulate it?

As it's such a low figure it's obviously got to be no-load - they use such ratings because it's easily testable, and it makes the motor 'look good'.

If you believe that's a loaded figure you're going to be sorely disappointed

For a transformer-rectifier, the transformer will need to be something from 15V to 18V depending on ratings and quality - that will give around 24V after rectification and smoothing. You need a reasonably well smoothed supply otherwise the motor load and power will be very uneven and the gearboxes are likely to wear rather faster..

A transformer with 24vdc secondary and a bridge will give you close enough to 24vdc, no filter required for inductive/motor devices.

But after ignoring advice across 3 forums, I suggest the OP go for the SMPS supply he is bent on using and see if it stands up.

Max.

I'm set on this DC motor: https://www.banggood.com/775-Gear-M...tail-top-buytogether-auto__2&cur_warehouse=CN

That's why I suggested higher voltage (24V means half current and lower losses) and a 1000W power unit, to run just a few motors: