I'm trying to fix a log splitter that got left in the rain. The motor is a capacitor-run single phase induction motor, with a rating between about 1 kW and 2 kW. It's about 20 cm diameter over the cooling fins.

The armature had rusted and jammed, but I have freed that off and the motor runs fine, but I still have a problem with earth leakage.

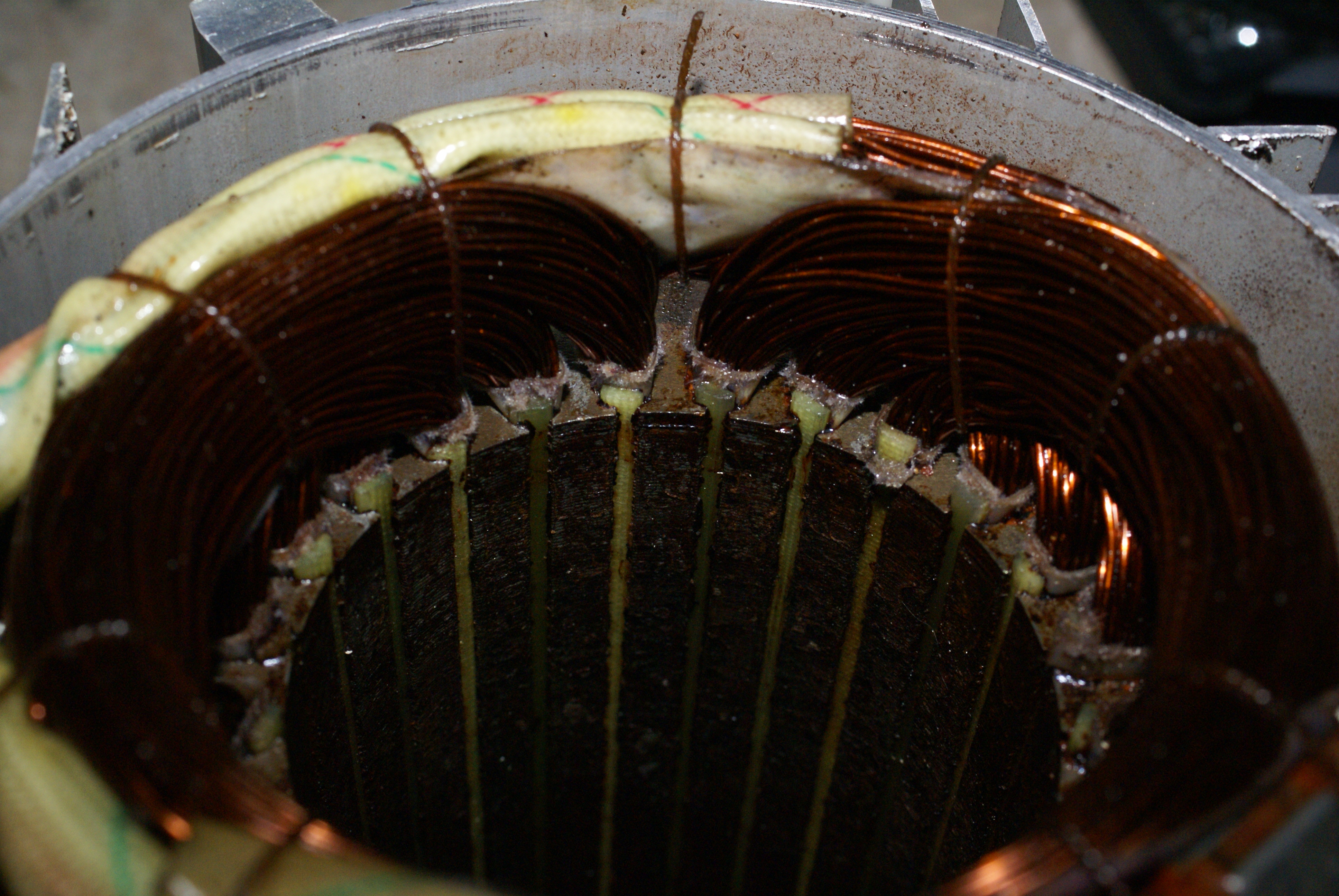

I've got the stator separate from the rest of the motor. There is about 2 mA leakage between the windings and the lamination at 240 V ac. When measured with a multimeter there is something electrochemical going on. In one direction it reads about 3 MOhm, and in the other direction, the reading climbs to about 20 MOhm, and when I immediately read the dc voltage, it's often above 2 V, and decays to zero. The multimeter puts out well over 3 V when measuring high resistances.

Although there is some rust on the laminations, I can't see any damage to the insulation around the winding bundles, but of course it's difficult to inspect everywhere and I can't get to look at most of the insulation without destroying the windings.

Any suggestions as to how I could deal with this without getting it rewound?

The armature had rusted and jammed, but I have freed that off and the motor runs fine, but I still have a problem with earth leakage.

I've got the stator separate from the rest of the motor. There is about 2 mA leakage between the windings and the lamination at 240 V ac. When measured with a multimeter there is something electrochemical going on. In one direction it reads about 3 MOhm, and in the other direction, the reading climbs to about 20 MOhm, and when I immediately read the dc voltage, it's often above 2 V, and decays to zero. The multimeter puts out well over 3 V when measuring high resistances.

Although there is some rust on the laminations, I can't see any damage to the insulation around the winding bundles, but of course it's difficult to inspect everywhere and I can't get to look at most of the insulation without destroying the windings.

Any suggestions as to how I could deal with this without getting it rewound?