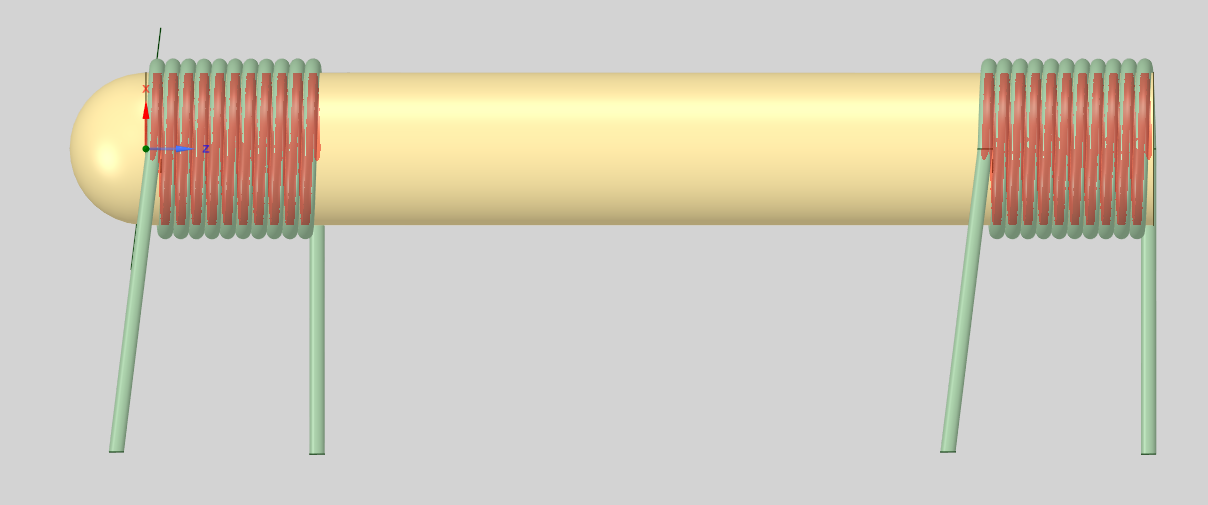

Another thought. If you wrapped wire around closely, you get a contact pattern as shown here in red

If you oversoldered it -- whilst it wouldn't wet the ceramic -- is would fill (some of) the voids and achieve a far greater area of contact.

Maybe overkill, but you might as well try and get as much of your current to flow through the ceramic, rather and just generating local hots spots.

Its a thought.

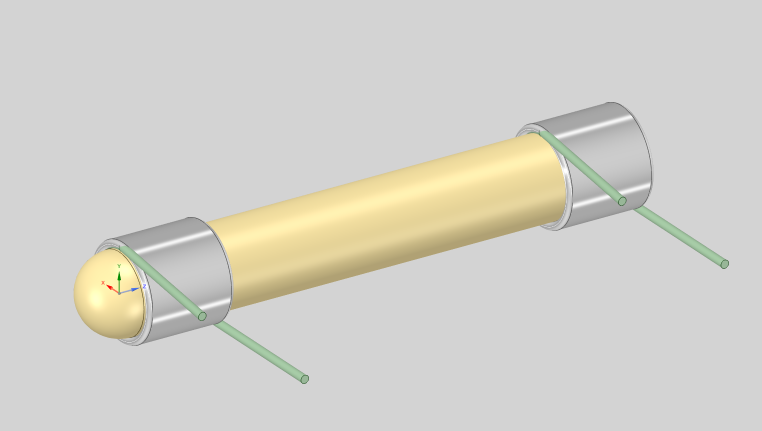

If you oversoldered it -- whilst it wouldn't wet the ceramic -- is would fill (some of) the voids and achieve a far greater area of contact.

Maybe overkill, but you might as well try and get as much of your current to flow through the ceramic, rather and just generating local hots spots.

Its a thought.