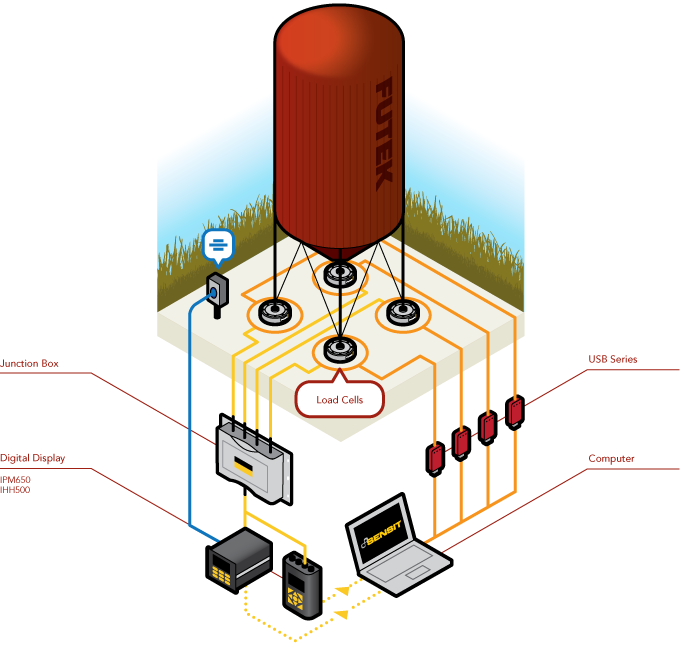

If you can lift the silo, Load cells are a great option.

https://www.futek.com/application/load-cell/Silo-Measurement

https://www.futek.com/application/load-cell/Silo-Measurement

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

We generally refer those concerns to their engineering support services. They've been very responsive to these kinds of application related questions (as most instrumentation companies are).Point level in liquids or granules?

Their inability to completely address static discharge is concerning (specifically for plastic pellets)...

https://www.drexelbrook.com/-/media...te-electrostatic-hazards-in-granular-bins.pdf

That should work. It's a sufficiently large area that there is little likelihood of the beads forming an air-trapping 'tent' over the plate (which would reduce the pressure on the plate).I like the idea of say a 12" square fastened to the bottom with a load cell attached

Well that kinda poo poo's that then, still good to know however.

The tank remains part full all the time, or the plant would shut.

So the way to do that the would be to use the bladder idea.

Or something I came up with is a 'rope' of 20 capacitive proxy's dangled into the silo.

5% tolerance is good enough, your right this is just a 'fuel guage', refills can be 2 times a week to 2 weeks.

However the silo is hardly ever empty, wont drifit accumulate, or will it just hover around a few %.

The proxy's seem like a good idea, ready made and can be just dangled in from the top.