It would be fun to share some circuits that you are proud of, impressed of, or just simply enjoyed designing.

Post your circuits (and stories). Anything goes from the simplest circuits to complete systems.

I'll start.

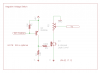

This is one circuit that I enjoyed working out. How to drive a (two leg) bi-color LED using two microcontroller pins.

The challenge was that the two LEDs needed to be "tuned individually" for proper current/brightness.

This was my solution:

**broken link removed**

(sorry for bad symbol for 2-legged bi-color led)

Example assuming 5V operating voltage:

If R2 = 160 ohms and R1 = 3300 ohms then the

current for 2.0V red led is 18.2 mA and the

current for 2.2V green led is 18.3 mA. And the

"wasted" current through R1 while the red led is lit, is 0.6 mA.

Below are schematics for the two states:

**broken link removed**

If you want the LED currents to be exactly the same, then:

R1 = R2*(V+Vr-Vg) / (Vg-Vr)

where V is supply voltage, Vr and Vg are the green and red led voltages and R1, R2 are the resistors.

Original problem is in ETO: https://www.electro-tech-online.com/threads/challenge-of-the-day-dual-color-led.120564/

Post your circuits (and stories). Anything goes from the simplest circuits to complete systems.

I'll start.

This is one circuit that I enjoyed working out. How to drive a (two leg) bi-color LED using two microcontroller pins.

The challenge was that the two LEDs needed to be "tuned individually" for proper current/brightness.

This was my solution:

**broken link removed**

(sorry for bad symbol for 2-legged bi-color led)

Example assuming 5V operating voltage:

If R2 = 160 ohms and R1 = 3300 ohms then the

current for 2.0V red led is 18.2 mA and the

current for 2.2V green led is 18.3 mA. And the

"wasted" current through R1 while the red led is lit, is 0.6 mA.

Below are schematics for the two states:

**broken link removed**

If you want the LED currents to be exactly the same, then:

R1 = R2*(V+Vr-Vg) / (Vg-Vr)

where V is supply voltage, Vr and Vg are the green and red led voltages and R1, R2 are the resistors.

Original problem is in ETO: https://www.electro-tech-online.com/threads/challenge-of-the-day-dual-color-led.120564/

Last edited: