Hello! First time poster. I've read the original "grid-tie inverter schematic" thread several times through, and now am reading this one.

Little info about myself: I'm a beginner electronics student (My limited experience is mostly power-related electro-mechanical work). For three years I worked as a traveling technician for one of the major multi-megawatt wind turbine manufacturers. (the BIG ones - I've climbed many 260 foot ladders.. I have worked at several of the wind farms in ND - tcmtech knows what I'm talking about) Part of technician training involved the converter portion of the turbine. Like most electronics, they are simple in theory, complex in practice. But they do use PWM to create a sine wave and sync it to the grid. Because they are industrial units, designed for rugged use, they have a wide variety of protective and control circuits (i.e.: over-current, over/under voltage, over/under frequency, power-factor, TVSS, remote-controlled power demand/limitation, etc.) that compliment the power circuits. The main switching was done using liquid-cooled IGBTS operating on 575 VAC 3-phase (newer designs used 690 VAC 3-phase). The work I did in that regard was mostly defective component troubleshooting and repair/replacement. Theoretical electronic design is not my strong suit, but I intend to change that - I quit my job to go back to school. I'm currently pursuing a B.S. in Electronics Engineering Technology, but I have only just begun (as the content of my forthcoming posts will no doubt betray - hehe).

So that may give you an idea about how little I know!

I'm fairly strong with mechanical disciplines, and electrical (power distribution and motors), but electronics is a new field to me.

Anyway, the idea of a grid-tie inverter has been on my mind long before I read these threads, but I really didn't have a starting point until I came here. The information that tcmtech, Jules Theone, Val Gretchev, be08be, and some others have played and experimented with seems very useful. Networking is great, isn't it! : )

In the near future, I may be helping a friend install (3) 20-kW turbines on his property. He purchased them at an auction as complete units. They are a Chinese brand, and the schematics and documentation are obviously transliterated, making them somewhat difficult to understand. 135-foot towers, 3-phase generators and rotors w/blades, control electronics (yaw, shutdown, dump-load, power display), and inverters. The inverters are single-phase, though, and I'm concerned about having (3) 20-kW inverters running on the same phase, primarily because the local power company here recommends that single-phase generators be limited to 10-kW or less. I'm assuming they would prefer to have anything larger generate 3-phase (since that is what the main generation facilities (coal, natural gas, nuclear, etc) output and what the transmission, secondary, and distribution (I think?) run on) so a single-phase doesn't have an unbalanced load on it back to the grid. We haven't gotten to the point of inquiring with the utility company about how to overcome this issue, or what potential solutions exist (split the output among the phases?).

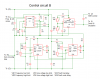

But after reading these threads, and pondering for over a month (I'm slow, ok..) I thought perhaps tcmtech's GTI 2.0 could be used in a 3-phase configuration. I drew up this crude schematic, based upon the GTI 2.0 schematic. The question I have is: would this work? From what I know, the control electronics would (in principal) be the same, gating the IGBTs based on the AC alternations, with appropriate zero-crossing dead-band delays, and protective anti-islanding, droop-frequency, voltage transient protection, etc. Of course, a 3-phase transformer would be necessary, which is essentially 3 separate transformers. I have attempted to draw the WYE/DELTA configurations in the schematic (I think they are correct - I'm not 100% sure - someone correct me if I'm wrong).

I have a feeling this would work, b/c I have seen a somewhat similar concept drawing within the technical documentation of the large frequency converters that I used to work on.

(They're called frequency converters b/c the output from the wind-turbines' generator is variable-frequency, variable-voltage AC. The converter rectifies it into DC, and PWMs it to AC. In actuality, the generators are DFIG (doubly-fed induction generators) and the stator remains a constant 60 Hz AC, while the rotor is fed with a variable slip frequency to combine with it's mechanical 'frequency' to induce an additive 60 Hz into the stator. They operate in sub-synchronous and super-synchronous mode (doesn't spend too much time at synchronous, b/c the IGBTs would be gating DC onto the rotor - almost full on/off). But anyway..

Is this possible? What other considerations need to be addressed?