GH Crash

Member

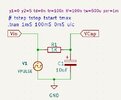

Any suggestions on how to reduce the resistance of the attached circuit.

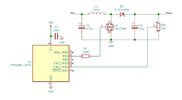

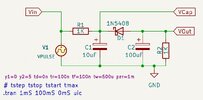

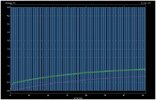

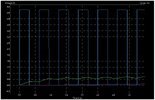

A supercapacitor (EDLC) is used to power a small motor. There is an ATTiny85 chip in the circuit that is used as a timer and a PWM controller for the motor. The problem that I'm loosing about half a volt between the capacitor's voltage and the voltage across the motor's leads. I need to minimize losses in the circuit as much as possible.

Can you suggest means to reduce voltage loses to the motor?

A supercapacitor (EDLC) is used to power a small motor. There is an ATTiny85 chip in the circuit that is used as a timer and a PWM controller for the motor. The problem that I'm loosing about half a volt between the capacitor's voltage and the voltage across the motor's leads. I need to minimize losses in the circuit as much as possible.

Can you suggest means to reduce voltage loses to the motor?