ThomsCircuit

Well-Known Member

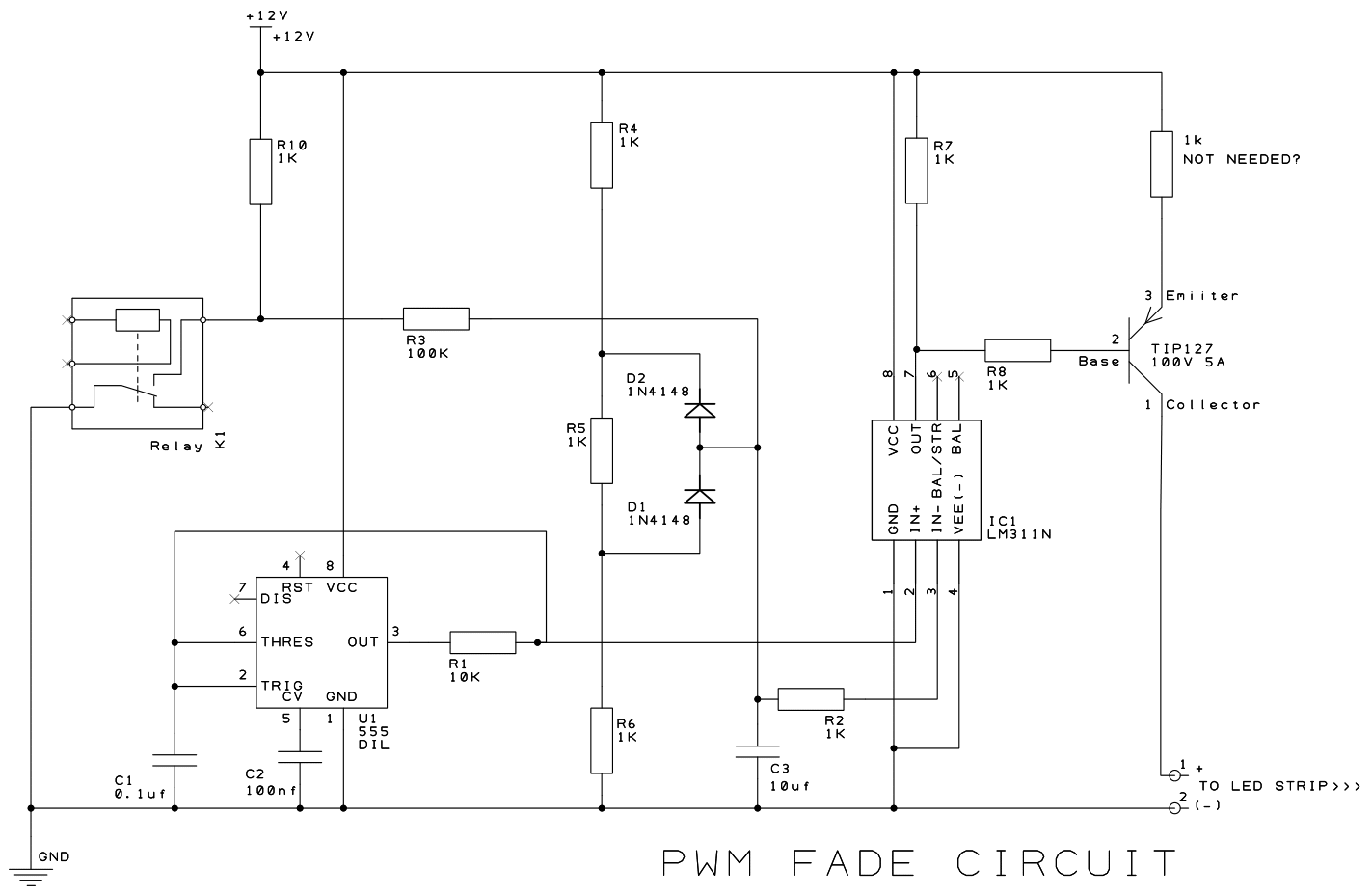

Condensed Schematic. Relay connected wrong

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

Ok. So ill just put the npn back and connect it to the collector.I think you have a double inversion now; for low=on, either swapping the 311 inputs or using a PNP output; not both.

I believe so! (Though I've not got my caffeine levels fixed yet this morningDid I get it right?

www.officialhrm.com

www.officialhrm.com

I can recognize some of the routines and variable declarations from my programming days. The compact design of the hardware makes for a very small footprint. Something i like.One simple way, use ATTINY85 to do supply sensing and PWM generation.

Do I need this resistor? I believe you had it here for the single led but it is no longer nessasary.I believe so! (Though I've not got my caffeine levels fixed yet this morning)

i don't follow you. curious...hi

If you replace the relay contact with the output of a second 555, the circuit could be made to alternately fade/on and fade/off automatically.

ok done. i do have top and bottom ground planes. just took them off to show the tracks. DS obscures the tracks after their poured.make the top side a ground plane; again, there is no reason not to, and it eliminates ground track width problems.

i don't follow you. curious...

when the relay is closed the light fades on and when it opens the light fades off. what would be automatically done.

ok done. i do have top and bottom ground planes. just took them off to show the tracks. DS obscures the tracks after their poured.

If I make the tracks any wider than 25 i get drill errors in the design check. ive read that it is ok (old tech) but ive also read that its not.View attachment 135218

I thought so. This project i need the fade on to only occur once when the relay closes and then fade off after the relay opens again.You wouldn't have to manually initiate a fade-on or a fade-off.

a small copper plane? like a copper shape that i add (not to the entire board) then pour? Id like to do this. How?The PWR track from the power input (wherever that is) to the light could be a small copper plane on the top side.

Just trying this out.

I replaced the full top copper pour GND with 2 polygon areas. the lower is a top pour for 12V and the upper area (remainder) is a GND pour.

This is to give as much copper as possible to the important areas. did I get this correct?

View attachment 135219

NOTE: I left out the bottom pour (GND) so you can see the top pour.