dobbsincrete

New Member

I am building a 5v humidity control for my bathroom extractor fan.

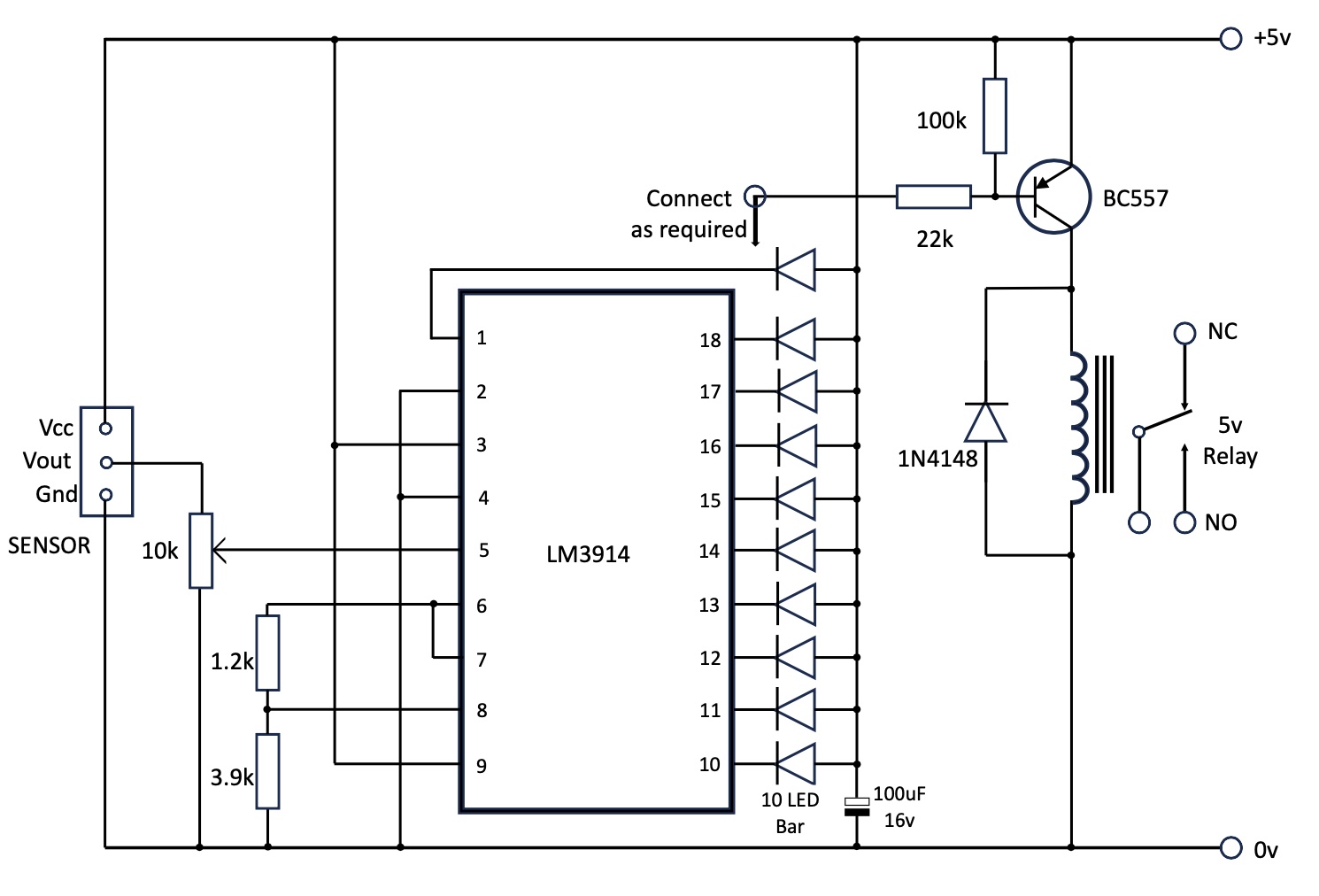

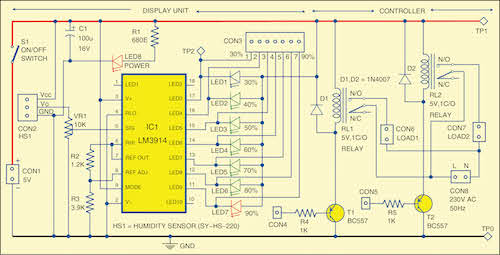

The circuit, (image attached), is based on information I have read on the internet and uses an LM3914, an led bar graph, a transistor and a 5v relay. The humidity sensor I have is the Velleman mm102. Seemed like a nice little project, but …..

I am having a problem with the transition between the LM3914 outputs.

As the humidity level changes, and the selected led level comes in to play, the transition, if slow, causes the transistor to not switch cleanly. This then makes the relay buzz briefly and the contacts not operating or releasing cleanly.

Does anyone have a way around this please?

Any help or guidance would be much appreciated.

Thank you

The circuit, (image attached), is based on information I have read on the internet and uses an LM3914, an led bar graph, a transistor and a 5v relay. The humidity sensor I have is the Velleman mm102. Seemed like a nice little project, but …..

I am having a problem with the transition between the LM3914 outputs.

As the humidity level changes, and the selected led level comes in to play, the transition, if slow, causes the transistor to not switch cleanly. This then makes the relay buzz briefly and the contacts not operating or releasing cleanly.

Does anyone have a way around this please?

Any help or guidance would be much appreciated.

Thank you

. My solution makes the relay work and has nothing to do with hysteresis. Why are you complaining about that? Did you understand my answer?

. My solution makes the relay work and has nothing to do with hysteresis. Why are you complaining about that? Did you understand my answer?