Mike - K8LH

Well-Known Member

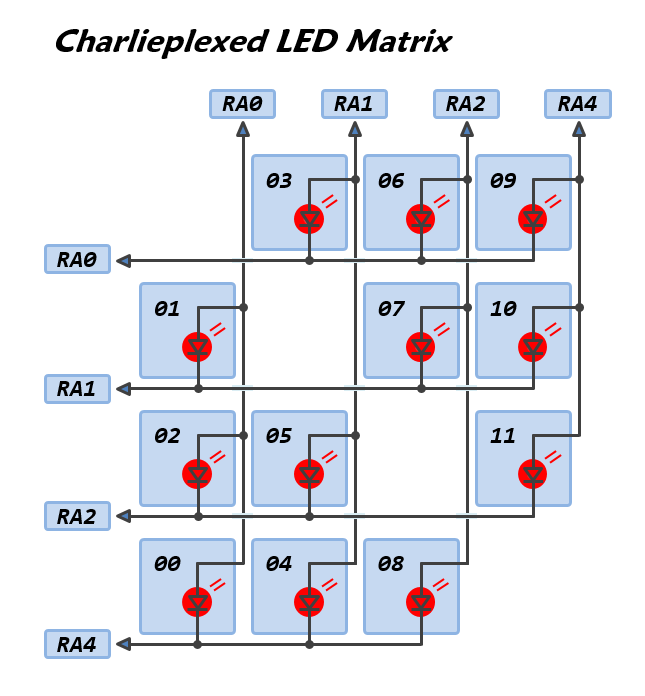

Would you be interested in a Charlieplexed display with a hi-speed hi-rez BAM driver for 12F1840 or 16F18313?

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

Would you be interested in a Charlieplexed display with a hi-speed hi-rez BAM driver for 12F1840 or 16F18313?

View attachment 125287

Does it have a Port B if it only has 8 pins? I looked through the datasheet and didn't see a reference to Port B.

So Charlie-Plexing is the only way to add more LEDs? So, if I do that, I need to change the pins to in & out, which will add to the complexity of the programming. I told myself that I needed to study and read more...lol I need to quite goofing around and get to reading.

It's an 8 pin PIC, it only has RA0 - RA5.To use RA7 instead of RA3.

You are correct, RA3 is input only, having just tried it..

The datasheet starts out saying "6 I/O" - but it also refers to a footnote saying one is input only; I missed that.

I thought the config bit to disable external reset allowed full function - but I never tested it.

ledout = calc_pwm(LED_P0);

if(ledout == 1) {

outimg = outimg | 0x01;

}

else {

outimg = outimg & ~0x01;

}

// The same sequence for the next:

ledout = calc_pwm(LED_P1);

if(ledout == 1) {

outimg = outimg | 0x02;

}

else {

outimg = outimg & ~0x02;

}

// And again for each pin, passing the phase offset

// then setting the appropriate pin

ledout = calc_pwm(LED_P2);

if(ledout == 1) {

outimg = outimg | 0x04;

}

else {

outimg = outimg & ~0x04;

}

ledout = calc_pwm(LED_P3);

if(ledout == 1) {

outimg = outimg | 0x10;

}

else {

outimg = outimg & ~0x10;

}

ledout = calc_pwm(LED_P4);

if(ledout == 1) {

outimg = outimg | 0x20;

}

else {

outimg = outimg & ~0x20;

}The interrupt driven BAM (Bit Angle Modulation) driver takes care of that for you. A small program reads records from an array (table) that contains brightness levels for each LED (0..31) plus a duration value. The BAM driver provides 32 linear brightness levels spanning a 256 step (250-uS steps) period for each LED and the entire 12 LED display is refreshed every 768-usecs (1302-Hz refresh rate)... This is a high performance method that's probably over-kill for your application...So Charlie-Plexing is the only way to add more LEDs? So, if I do that, I need to change the pins to in & out, which will add to the complexity of the programming. I told myself that I needed to study and read more...lol I need to quite goofing around and get to reading.

/*

* Rotating strobe simulator

*

* (C) 2020 Robert Jenkins

* Released under GNU GPL licence.

*

* This version made to be buildable

* using MPLAB X and the free XC8 compiler

*

*/

// PIC16F18313 Configuration Bit Settings

// 'C' source line config statements

// CONFIG1

#pragma config FEXTOSC = OFF // FEXTOSC External Oscillator mode Selection bits (Oscillator not enabled)

#pragma config RSTOSC = HFINT32 // Power-up default value for COSC bits (HFINTOSC with 2x PLL (32MHz))

#pragma config CLKOUTEN = OFF // Clock Out Enable bit (CLKOUT function is disabled; I/O or oscillator function on OSC2)

#pragma config CSWEN = ON // Clock Switch Enable bit (Writing to NOSC and NDIV is allowed)

#pragma config FCMEN = ON // Fail-Safe Clock Monitor Enable (Fail-Safe Clock Monitor is enabled)

// CONFIG2

#pragma config MCLRE = OFF // Master Clear Enable bit (MCLR/VPP pin function is digital input; MCLR internally disabled; Weak pull-up under control of port pin's WPU control bit.)

#pragma config PWRTE = OFF // Power-up Timer Enable bit (PWRT disabled)

#pragma config WDTE = OFF // Watchdog Timer Enable bits (WDT enabled, SWDTEN is ignored)

#pragma config LPBOREN = OFF // Low-power BOR enable bit (ULPBOR disabled)

#pragma config BOREN = ON // Brown-out Reset Enable bits (Brown-out Reset enabled, SBOREN bit ignored)

#pragma config BORV = LOW // Brown-out Reset Voltage selection bit (Brown-out voltage (Vbor) set to 2.45V)

#pragma config PPS1WAY = ON // PPSLOCK bit One-Way Set Enable bit (The PPSLOCK bit can be cleared and set only once; PPS registers remain locked after one clear/set cycle)

#pragma config STVREN = ON // Stack Overflow/Underflow Reset Enable bit (Stack Overflow or Underflow will cause a Reset)

#pragma config DEBUG = OFF // Debugger enable bit (Background debugger enabled)

// CONFIG3

#pragma config WRT = OFF // User NVM self-write protection bits (Write protection off)

#pragma config LVP = OFF // Low Voltage Programming Enable bit (HV on MCLR/VPP must be used for programming.)

// CONFIG4

#pragma config CP = OFF // User NVM Program Memory Code Protection bit (User NVM code protection disabled)

#pragma config CPD = OFF // Data NVM Memory Code Protection bit (Data NVM code protection disabled)

// #pragma config statements should precede project file includes.

// Use project enums instead of #define for ON and OFF.

#include <xc.h>

#include <stdint.h>

// Pin configuration used with 16F18313

//

// 01 = VDD +5V

// 02 = RA5 LED 4

// 03 = RA4 LED 3

// 04 = RA3 / MCLR VPP for pprogramming

// 05 = RA2 LED 2

// 06 = RA1 LED 1

// 07 = RA0 LED 0

// 08 = VSS 0V

uint8_t pwmreg; //address configuration

uint8_t stepcount; //

uint8_t substep; // PWM cycles per step increment; speed setting

uint8_t outimg;

// Master, coarse speed setting value; larger is slower.

#define SUBSTEP_MAX 9

// PWM range 0-x; a (power of 2) - 1 value

// Using 0 - 31

#define PWM_MAX 0x1f

// Brightness steps for a full rotation sequence of one light;

// eg. 4 or 8 times the number of different-brightness lights, -1

// With a 32MHz clock, 120 steps can still run ludicrously fast.

#define STEP_MAX 120

// Output phase, equal offsets through the "step" cycle.

// eg. With 120 step table, 0-40-80 for three outputs,

// 0-30-60-90 for four, 0-24-48-72-96 for five,

// 0-20-40-60-80-100 for six and so on.

//

#define LED_P0 0

#define LED_P1 24

#define LED_P2 48

#define LED_P3 72

#define LED_P4 96

//#define LED_P5

//

// The association between LED numbers and output

// pins is created in each pin routine, further down.

//

// Look-up table for brightness sequence for one light

// Brightness range is from 0 (completely off) to PWM_MAX (always on)

uint8_t ltable1[STEP_MAX] =

// 120 Steps, 3' per step.

// This one is for a very narrow beam angle lens front, around 10'

// 180' to -138'

{0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0,

// -135' to -93'

0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0,

// -90' to -48'

0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0,

// -45' to -3'

0, 0, 0, 0, 0, 0, 1, 1, 1, 1, 1, 2, 4, 10, 24,

// Zero degrees to +42'

32, 24, 10, 4, 2, 1, 1, 1, 1, 1, 0, 0, 0, 0, 0,

// +45' to +87'

0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0,

// +90' to +132'

0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0,

// +135' to +177'

0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0};

uint8_t ltable2[STEP_MAX] =

// 120 Steps, 3' per step.

// This one is for a wide beam & open reflector, around 30'

// 180' to -138'

{0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0,

// -135' to -93'

0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0,

// -90' to -48'

0, 1, 1, 1, 2, 2, 2, 3, 3, 3, 4, 4, 5, 5, 6,

// -45' to -3'

6, 7, 8, 9, 10, 11, 12, 15, 24, 26, 28, 29, 30, 31, 31,

// Zero degrees to +42'

32, 31, 31, 30, 29, 28, 26, 24, 15, 12, 11, 10, 9, 8, 7,

// +45' to +87'

6, 6, 5, 5, 4, 4, 3, 3, 3, 2, 2, 2, 1, 1, 1,

// +90' to +132'

0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0,

// +135' to +177'

0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0};

// Function definition

uint8_t calc_pwm(uint8_t);

/*

*

*/

int main(int argc, char** argv) {

int8_t ledout;

outimg = 0;

pwmreg = 0;

stepcount = 0;

substep = 0;

// I/O Pin directions:

// All out: TRIS = 0x0000 0000

TRISA = 0x00;

// OSC = 32 MHz.

// Timer source = osc / 4; 8 MHz.

for(;;)

{

CLRWDT();

pwmreg = pwmreg + 1;

pwmreg = pwmreg & PWM_MAX;

// Do one LED > device pin bit at a time.

// Get the on/off state and set the appropriate output pin

// Outputs high for on; LED & resistor to 0V.

// The | / ~ number used is the hex value that puts a single bit on the appropriate output pin.

ledout = calc_pwm(LED_P0);

if(ledout == 1) {

outimg = outimg & ~0x01;

}

else {

outimg = outimg | 0x01;

}

// The same sequence for the next:

ledout = calc_pwm(LED_P1);

if(ledout == 1) {

outimg = outimg & ~0x02;

}

else {

outimg = outimg | 0x02;

}

// And again for each pin, passing the phase offset

// then setting the appropriate pin image in outimg

ledout = calc_pwm(LED_P2);

if(ledout == 1) {

outimg = outimg & ~0x04;

}

else {

outimg = outimg | 0x04;

}

ledout = calc_pwm(LED_P3);

if(ledout == 1) {

outimg = outimg & ~0x10;

}

else {

outimg = outimg | 0x10;

}

ledout = calc_pwm(LED_P4);

if(ledout == 1) {

outimg = outimg & ~0x20;

}

else {

outimg = outimg | 0x20;

}

/*

ledout = calc_pwm(LED_P5);

if(ledout == 1) {

outimg = outimg & ~0x20;

}

else {

outimg = outimg | 0x20;

}

*/

//

// Set all the pins in the port simultaneously

// by copying outimg to the port register.

//

PORTA = outimg;

//

// Or use PORTA = ~outimg;

// and comment out the above line,

// if you need pins high for light on

//

// PORTA = ~outimg;

//

// For larger devices with two or more ports, use two or

// more outimg - eg. outimga & outimgb

// processing each bit as abovem then copying both to the

// respective ports.

//

// Add a few microseconds delay here to give a sine speed adjustment.

// Change the

// At each 0 of the PWM reg, count the substep delay

// and if that overflows, move to the next sequence step.

if(pwmreg == 0) {

//

// Substep limit sets the overall cycle speed

substep = substep + 1;

if(substep > SUBSTEP_MAX) {

substep = 0;

stepcount = stepcount + 1;

if(stepcount >= STEP_MAX)

{

stepcount = 0;

}

}

}

}

return (1);

}

uint8_t calc_pwm (uint8_t lp) {

uint8_t x, y;

// Work out the cycle stage for the lamp, then get the table brightness

// and compare to the PWM count to determine on/off

x = stepcount + lp;

// Wrap the result back to the start of the table;

// if it is beyond the end.

if(x >= STEP_MAX) {

x = x - STEP_MAX;

}

// Get the brightness value from the table

// Use ltable1 or ltable2 as appropriate.

y = ltable2[x];

// Compare to present PWM value to determine on or off

if(y > pwmreg) {

return 1;

}

return 0;

}void interrupt ISR() // Michael McLaren, K8LH

{ static unsigned char step = 0;

static unsigned char toggle[64] = { 0,0,0,0,0,0,0,0,0,0,0,0,0,0,0,0,

0,0,0,0,0,0,0,0,0,0,0,0,0,0,0,0,

0,0,0,0,0,0,0,0,0,0,0,0,0,0,0,0,

0,0,0,0,0,0,0,0,0,0,0,0,0,0,0,0 };

PORTB ^= toggle[step]; // update channel outputs

toggle[step] = 0; // clear element for next period

step++; //

if(step == 64) // if end-of-period

{ step = 0; //

toggle[led[0]] |= 1; // insert LED 0 toggle bit

toggle[led[1]] |= 2; // insert LED 1 toggle bit

toggle[led[2]] |= 4; // insert LED 2 toggle bit

toggle[led[3]] |= 8; // insert LED 3 toggle bit

toggle[led[4]] |= 16; // insert LED 4 toggle bit

toggle[led[5]] |= 32; // insert LED 5 toggle bit

toggle[led[6]] |= 64; // insert LED 6 toggle bit

toggle[led[7]] |=128; // insert LED 7 toggle bit

toggle[0] ^= ~PORTB; // initialize first toggle element

} //

TMR0 = 210; // adjusts step size & frame rate

TMR0IF = 0; //

} //So, I can leave them commented the way they are as long as I select which one to use (ltable1 or ltable2) for "y" at the bottom? I added another table to see the differences.

So if I wanted to change the speed, do I change a combination or just one specific area.