Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

Thank you very much indeed, i grabbed a old boiler off ebay, they are well expensive here but it does have a flywheel and piston, this bit i can modify to make some the extras i was on about. So with two boilers i got more options.Well, I do have the boiler I made for it. Might as well send it also since I'll have no use for it. I was going to use Butane as the fuel. It has a pressure gauge (no idea how accurate) but no pressure regulator. I have no idea of its bursting pressure, so use at your own risk!!

This engine also has a shaft with NO ball bearings (look at the pic above of the TRV1A, above), so it has to be oiled regularly. There is, however, a ball bearing mod available:

View attachment 112899

I will say that the darn thing was a lot of fun to build and play with!

no where on that list is the fuel we are discussing! where in that list is BIO methane? Compressed natural gas is not BIO methane!! its a waste product from oil production

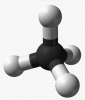

Oh dear you dont understand your own link! Ok want a small chemistry lesson?So if you rename CH4 from 'Natural Gas' To 'Biomethane' it somehow changes its properties in some drastic way?

https://www.uniongas.com/about-us/about-natural-gas/chemical-composition-of-natural-gas

**broken link removed**

So if you rename CH4 from 'Natural Gas' To 'Biomethane' it somehow changes its properties in some drastic way?

What your actually asking is one of two things, but you have worded it very badly. If i had Methane (CH4) and called it CNG, would i expect it to act differently to CH4? No obviously because its just Methane but i am calling it CNG.So if you rename CH4 from 'Natural Gas' To 'Biomethane' it somehow changes its properties in some drastic way?

to have different proprieties to a mix of

to have different proprieties to a mix of

and expect it to be different from

and expect it to be different from

is the same as CNG??? or maybe your trying troll me?

is the same as CNG??? or maybe your trying troll me? is the same as CNG? On a chemical level (and therefore property level) do you seriously think they react the same and have the same properties, like say boiling points and energy content? Before answering look at the bonds and go find data on the densities for ALL the gases in CNG and add them together then do the same for CH4. Do they work out the same?

is the same as CNG? On a chemical level (and therefore property level) do you seriously think they react the same and have the same properties, like say boiling points and energy content? Before answering look at the bonds and go find data on the densities for ALL the gases in CNG and add them together then do the same for CH4. Do they work out the same?

No you didnt read or didnt understand any of it did you? Ok tomorrow i will explain it very carefully so you see the difference, but first forget about Methane derived from oil etc, otherwise we wont get anywhere.So basically your 'clean Biomethane' (~95 - 99% CH4) is pretty much the same as commercial grade natural gas ((~95 -99% CH4)being the majority of commercial natural gas has been struipped of all of those secondary gases and when burned their averaged BTU contents fall within the exact same ranges of each other. Which in the theme of the thread in how to turn their chemical energy potential into electricity one is pretty much interchangeable for the other regardless of what engine or conversion process you are using to do it.

Now all said and done, thanks for the lessons in nothing I didn't already know, but how to make more false assumptions of others knowledge bases you know very little about, being I worked in the oil industry and studied (and still do) what all comes out of the wells I had to work on and where it all goes and what for once it hit the surface, which interestingly enough,bleeds over into my newer interests in fractional distillation processing of used antifreeze to get clean ethylene glycol and in the future perhaps doing the same process to used oil to see what all I can possibly squeeze out of that too.

FWIW, what I have been trying to point out is that in all rational factors your bio methane is in all likelihood so close the common commercial natural gas there is no major measurable differences in the two beyond your insistence in using a more eco friendly sounding name, which seems to be all the rage these days, for making the same old same old sound like its newer and better than it is. In an engine, turbine, boiler or fuel cell they are so close to each other you couldn't tell one from the other.

All things said and done we have very similar end goals here. You're just using newspeak fancy words and smoke and mirror explanation/obfuscation justifications for playing with common bio based CH4 fuel stock production methods and I am sticking with petroleum based stocks.

Not according to your own link! or indeed the journal literature, i will also explain why that is and where it comes from.So basically your 'clean Biomethane' (~95 - 99% CH4) is pretty much the same as commercial grade natural gas ((~95 -99% CH4)being the majority of commercial natural gas has been struipped of all of those secondary gases

make more false assumptions of others knowledge bases you know very little about

Can you point to the bit i said my Methane was 95-99% please as i need to correct that. Or did you guess a figure from another dodgy site? I used your links for the information, i even pointed out the link with contradiction in it. Out of interest what do you think methogens use to make Methane?

Really, thats a bit odd! look at my post above and your quote, this bitI never said your gas was 95 - 99% pure CH4

Thats all a bit jumbled, but just so we are clear..... Are you talking about my gas or commercial fossil fuel gas? Thi is a problem when you troll these threads, you use words all jumbled and in a way that dosnt really make it clear what your on about, its almost like you dont want to commit to something you might want to rescind later. Please dont do this, it really confuses others and wastes alot of time clearing it up.But since you seem to be against favorable equative comparison I now have to assume your methane is even less pure than the standards that commercial gas is made to plus, unlike commercial gas that has largely other combustible hydrocarbons as 'contaminants' yours does not but more than likely is loaded with incombustible CO2 (and some artificially induced/manufactured hydrogen) thusly lowering its effective start to finish BTU content more.

Not at all, many times i have stated in numerous threads you have taken part in that i try and preserve the CO2, I take it out the gas and use it as a CARBON SOURCE, seriously i have stated this so many times now, i have even detalied what i use it for and how i use it. Any i cant capture is neutralized with Sodium hydroxide solution, i even gave you the molarity of the solution in one post!yours does not but more than likely is loaded with incombustible CO2

Again this is wrong, i have also said in the posts i mention above the following....... We run systems that are GRID INJECTED, this means our gas HAS to reach the required standard before it can be injected into the national grid, the grid people actually put monitors on your pre injection point, they have a record of everything in your gas, and that dosnt meet standard is auto diver ted back into the system or you are simply shut out.But since you seem to be against favorable equative comparison I now have to assume your methane is even less pure than the standards that commercial gas is made to

No again, although this is a great example of one the big advantages of a multi chamber system, The main Hydrogen we inject or 'flush' in at the start to give a anaerobic atmosphere (in the anaerobic chambers anyway), The process metabolizes H+ ions and CO2 into Methane this is the entire point of these systems and yes some other systems flush with Nitrogen or CO2, we use Hydrogen and CO2(and some artificially induced/manufactured hydrogen) thusly lowering its effective start to finish BTU content more.

Again wrong, i have repeatedly asked you in various threads to use scientific journals or credible sources, I started doing that but it became clear you either were not reading the material provided or didnt understand it (fair enough seeing as scientific papers are written for scientists and not tinkerers), i used your source because i didnt want to be accused of using a source you didnt trust, i did point out while the first link you provided didnt match the data in scientific literature, it was close enough to prove the point i was making.As for 'educating me', going off on non relevant tangents really doesn't help me or anyone else understand what you are actually working with here. Actual line item lists of known or assumed ingredients and their sources does, which is what I was alluding to in those links, you seem to have misunderstood the point, of while at the same time using the very charts that show their calculatabel subcomponent values.

So if you rename CH4 from 'Natural Gas' To 'Biomethane' it somehow changes its properties in some drastic way?

What??You want to run it through an engine or converter system to turn it into electricity in the end so knowing what it likely energy content per unit of mass is needed to calculate the conversions actual working process efficiency, right?

Yes to engine, but not sure what your referring to as a "converter system", so i dot give misleading info can you explain exactly what you mean by converter system please.You want to run it through an engine or converter system to turn it into electricity in the end

in the end so knowing what it likely energy content per unit of mass is needed to calculate the conversions actual working process efficiency, right?

After all if you have to dope your produced Biomethane with artificially manufactured hydrogen to get its effective end process BTU content substantially up over what common commercial natural gases BTU content is for an equal mass and or volume that doesn't really count does it?

After all if you have to dope your produced Biomethane with artificially manufactured hydrogen to get its effective end process BTU content substantially up over what common commercial natural gases BTU content is

if you have to dope your produced Biomethane with artificially manufactured hydrogen to get its effective end process BTU content substantially up over what common commercial natural gases BTU content is

So educate me and everyone else on what your 'biomethane' really is. What is its known or assumed to be chemical/molecular subcomponent make up.

X% amount of CH4 + Y% amount of 2nd most substance and Z% amounts of what 3rd most substance and so on.

what your 'biomethane' really is. What is its known or assumed to be chemical/molecular subcomponent make up.

X% amount of CH4 + Y% amount of 2nd most substance and Z% amounts of what 3rd most substance and so on.

What is a chemical/molecular subcomponent? For example lets take water, what would you call the subcomponent of H2O? Its nonsensical again.chemical/molecular subcomponent make up

Others have stated a few times they are finding the information and posts useful and interesting,

your not really adding anything of use or much relevance, that spoils it for others.

Its not open publicly as such, its a spin off from our main company website (energy company), its mainly where those working on the actual projects swap information and the design stuff etc is done. I have mentioned it before, new customers also have access as each AD site has its own section and we can log into the SCADA systems from there. What we were thinking of doing is putting a blog type front end on that was more general and adding some extra sections.Where is that?

Do tell.

JimB

Try saying that fast! would make a great sobriety testYep, I am learning a lot and finding it very interesting. Thank you.

Ain't that the truth.

For some reason I keep thinking of a little plaque we had at home growing up ...

He who knows not and knows not he knows not, he is a fool—shun him;

He who knows not and knows he knows not, he is simple—teach him;

He who knows and knows not he knows, he is asleep—wake him;

He who knows and knows he knows, he is wise—follow him!

Lady Burton

Another side note, I get to visit a liquid salt boiler at a uni in a few weeks time. Brave people working with a molten salt at that temp!!

being the majority of commercial natural gas has been struipped of all of those secondary gases and when burned their averaged BTU contents fall within the exact same ranges of each other.