Popcorn failures are either from shoot-thru issues in general, may be caused by;

- complementary drivers with no dead time (thermal runaway)

- dielectric breakdown failures (arc trigger)

- reverse conduction failures

- CMOS I/O's exceeding Vdd,Vss

This failure occurred because the root cause was not adequately identified and then corrected.

None of the above failure modes can be corrected by slow front-end fusing.

I never found out if power is cycled on the input with something or not and what event if any coincided with the failure like "demand heat" on thermostat.

When I cut my teeth in the late '70's a major project (with about 40 new PCBs in the design, that I inherited, I worked late at night and , production mgr, would have a pile of rework instructions next morning for months. This was before simulators were invented so designs took a week and went right to PCB. In the end, I got everything working. (SCADA/Robotic/Eddy Current scanning subsystem)

This kind of problem is really hard to isolate in without a lot of prior circuit experience on the transient nature of signals. Simple failed component failures are easy to fix. Popcorn chain reactions are harder.

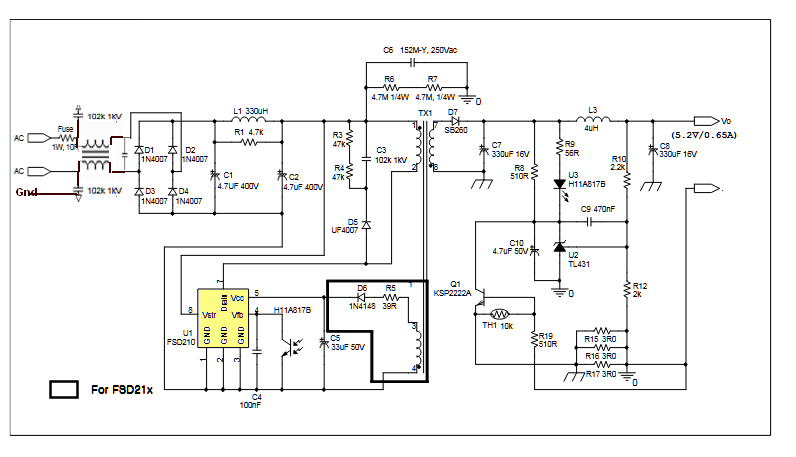

You can update the schematic if you like for your own learning curve.

Failures are the best experience. I've made many errors and seen many others to fix at the design or production stage.

- complementary drivers with no dead time (thermal runaway)

- dielectric breakdown failures (arc trigger)

- reverse conduction failures

- CMOS I/O's exceeding Vdd,Vss

This failure occurred because the root cause was not adequately identified and then corrected.

None of the above failure modes can be corrected by slow front-end fusing.

I never found out if power is cycled on the input with something or not and what event if any coincided with the failure like "demand heat" on thermostat.

When I cut my teeth in the late '70's a major project (with about 40 new PCBs in the design, that I inherited, I worked late at night and , production mgr, would have a pile of rework instructions next morning for months. This was before simulators were invented so designs took a week and went right to PCB. In the end, I got everything working. (SCADA/Robotic/Eddy Current scanning subsystem)

This kind of problem is really hard to isolate in without a lot of prior circuit experience on the transient nature of signals. Simple failed component failures are easy to fix. Popcorn chain reactions are harder.

You can update the schematic if you like for your own learning curve.

Failures are the best experience. I've made many errors and seen many others to fix at the design or production stage.