LipschitzWrath

New Member

Hey guys, need some expertise here. I have some +12V lights powered off a +12V bosch relay. The old lights for the application used to be powered directly. The relay was installed and the coil is being controlled off the old wire that used to be hooked to the bulbs directly.

The system controlling it doesn't go straight on or off. When it is on, rather than turning off, it first begins to dim the bulb using PWM. Once the PWM reaches a nominal (and unknown) level, it shuts off completely. Obviously, the relay doesn't like this PWM at all. It makes a terrible buzzing noise during the entire PWM cycle as it opens and closes a billion times a second. I'm sure this isn't good for lifespan.

I'd like to get rid of the PWM signal, or at least overcome it so that I get the effect of a straight on or off. I have tried SSR's and they don't work. So I need some help. How do I do this?

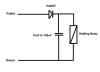

I thought maybe a transistor as its saturation voltage is much lower than the pull in or hold in voltage of the relay coil. Would that work? I don't know how a transistor would respond to having a PWM signal applied to its base.

The other option is to filter it out with an R-C network right? Any ideas there?

Now for the bad news. I don't know the duty cycle, decay rate, or frequency of the PWM signal. I don't have an oscilloscope either. I have a DMM and am quite handy with it.

Looking for help here. Got chewed out at another forum for asking the question so I am posting it here.

The system controlling it doesn't go straight on or off. When it is on, rather than turning off, it first begins to dim the bulb using PWM. Once the PWM reaches a nominal (and unknown) level, it shuts off completely. Obviously, the relay doesn't like this PWM at all. It makes a terrible buzzing noise during the entire PWM cycle as it opens and closes a billion times a second. I'm sure this isn't good for lifespan.

I'd like to get rid of the PWM signal, or at least overcome it so that I get the effect of a straight on or off. I have tried SSR's and they don't work. So I need some help. How do I do this?

I thought maybe a transistor as its saturation voltage is much lower than the pull in or hold in voltage of the relay coil. Would that work? I don't know how a transistor would respond to having a PWM signal applied to its base.

The other option is to filter it out with an R-C network right? Any ideas there?

Now for the bad news. I don't know the duty cycle, decay rate, or frequency of the PWM signal. I don't have an oscilloscope either. I have a DMM and am quite handy with it.

Looking for help here. Got chewed out at another forum for asking the question so I am posting it here.