Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

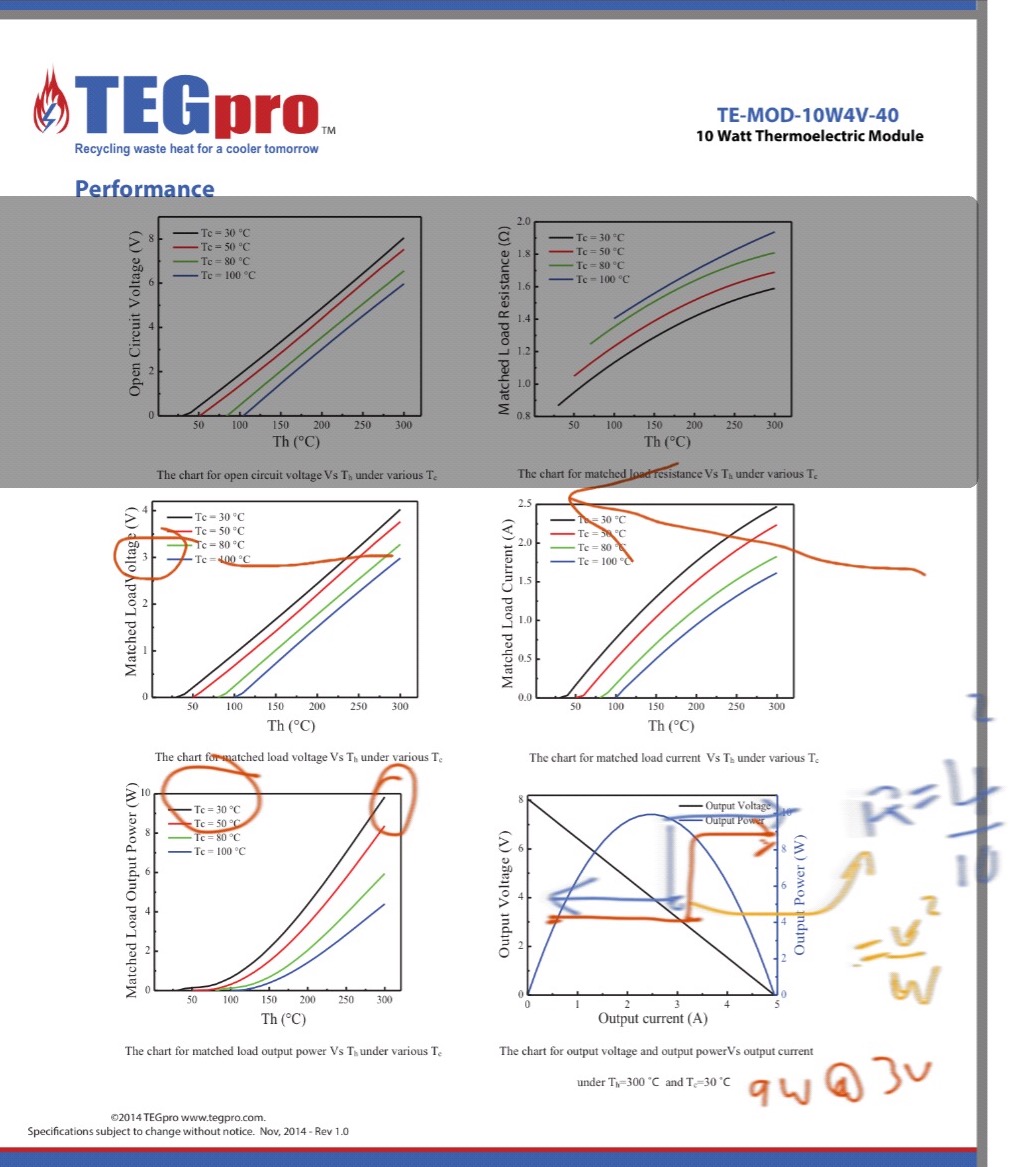

View attachment 100350

One idea for the single cell project.

The "SW" is set to turn on at 1.7V and off at 1.0V.

Boost maximum is 1.75V Probably should be set to 2V.

Not running exactly at "max power point" but close. It will take many more parts to run exactly at max power.

Some time I should find out what you do. (off line) I think we have much in common.You are

Same here-Some time I should find out what you do. (off line) I think we have much in common.

Many time while I slowly type your post the answer. LOL

Off to work I go.

One idea for the single cell project.

The "SW" is set to turn on at 1.7V and off at 1.0V.

Boost maximum is 1.75V Probably should be set to 2V.

Not running exactly at "max power point" but close. It will take many more parts to run exactly at max power.

No probs Matienzo.Ron and Spec, that is amazing. I still need to understand what you guys did there and it will take me a couple of hours (at least) but this is all I'm doing today

I'll be back with questions...

There are separate approaches from Ron and me.

You must use the components as specified, especially the PMOSFET shown in the schematic of post #54.