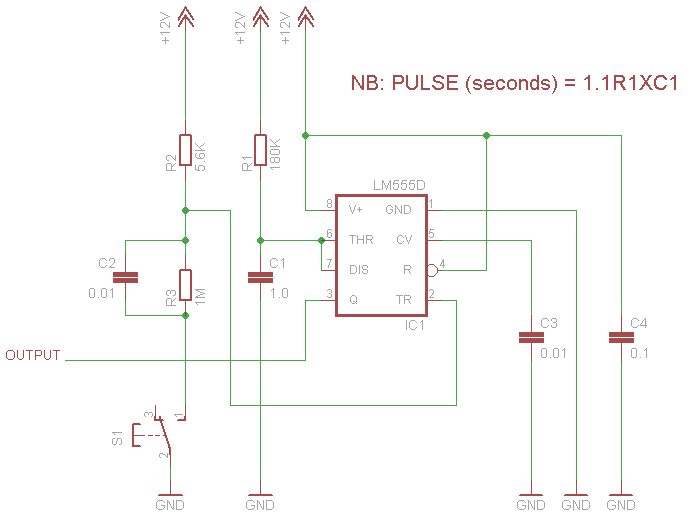

The timing circuit I used for my MOT welder was based on a circuit from MIT. As I mentioned above, the datasheet for a 555 will show how to wire it as a monostable to give a single pulse that will activate your relay for the desired time. The trigger (TR, pin#2) for the 555 must be brought low (i.e., grounded) to initiate the timing. If the trigger is held low, the 555 can continually reset. The **broken link removed** solves that problem and adds debouncing. (Edit: That link to the MIT site appears to be broken, or my ISP is not working right. Sorry about that.) The latter prevents multiple pulses (or an uncertain pulse duration), which can be caused by bouncing of the switch contacts as they close.

How it works is explained fully on the MIT link. In brief, when S1 is closed, the circuit from your positive supply is completed across C2, which acts briefly as a short to ground and initiates the trigger. As C2 charges, the voltage at the TR pin increases because of the voltage divider formed by R2 and R3. Thus, re-triggering is prevented if you leave the switch closed. Since we anticipate that the welding time (i.e., the pulse width) will be quite short, I believe that including that aspect in the circuit is important.

The attached schematic has values calculated to give about a 200 mS pulse (i.e., 10 cycles at 50 Hz). You can change the values of R1 and C1 as needed to get any pulse duration you want. I show a 12V power supply. A typical 555 (i.e., LM555C) can operate from 4.5 to 16V. For testing, I would suggest that you simply use a 9V battery. If that works, then you may want a longer lasting supply for routine use.

As for how to connect it, see the 5 Bears reference I gave above. It is really simple. The trigger circuit controls the relay, and the relay controls the input supply to your transformer.

John

How it works is explained fully on the MIT link. In brief, when S1 is closed, the circuit from your positive supply is completed across C2, which acts briefly as a short to ground and initiates the trigger. As C2 charges, the voltage at the TR pin increases because of the voltage divider formed by R2 and R3. Thus, re-triggering is prevented if you leave the switch closed. Since we anticipate that the welding time (i.e., the pulse width) will be quite short, I believe that including that aspect in the circuit is important.

The attached schematic has values calculated to give about a 200 mS pulse (i.e., 10 cycles at 50 Hz). You can change the values of R1 and C1 as needed to get any pulse duration you want. I show a 12V power supply. A typical 555 (i.e., LM555C) can operate from 4.5 to 16V. For testing, I would suggest that you simply use a 9V battery. If that works, then you may want a longer lasting supply for routine use.

As for how to connect it, see the 5 Bears reference I gave above. It is really simple. The trigger circuit controls the relay, and the relay controls the input supply to your transformer.

John

Attachments

Last edited: